GRIP Base Connector SWS

Assembly and Operating Manual

7 Maintenance and care

7.1 Disassembly of the Base Connector SWS

(Behold Image 5)

1.

Disassemble the Base Connector

2.

Loosen the Setscrew (Pos. 3).

3.

4.

Clean all parts thoroughly. Inspect for wear and defects.

5.

Lubricate all mating surfaces.

For assembly, reverse the order.

7.2 Torque specifications

M6 – 8,5 Nm; M8 – 20,6 Nm; M10 – 41 Nm; M12 – 71 Nm

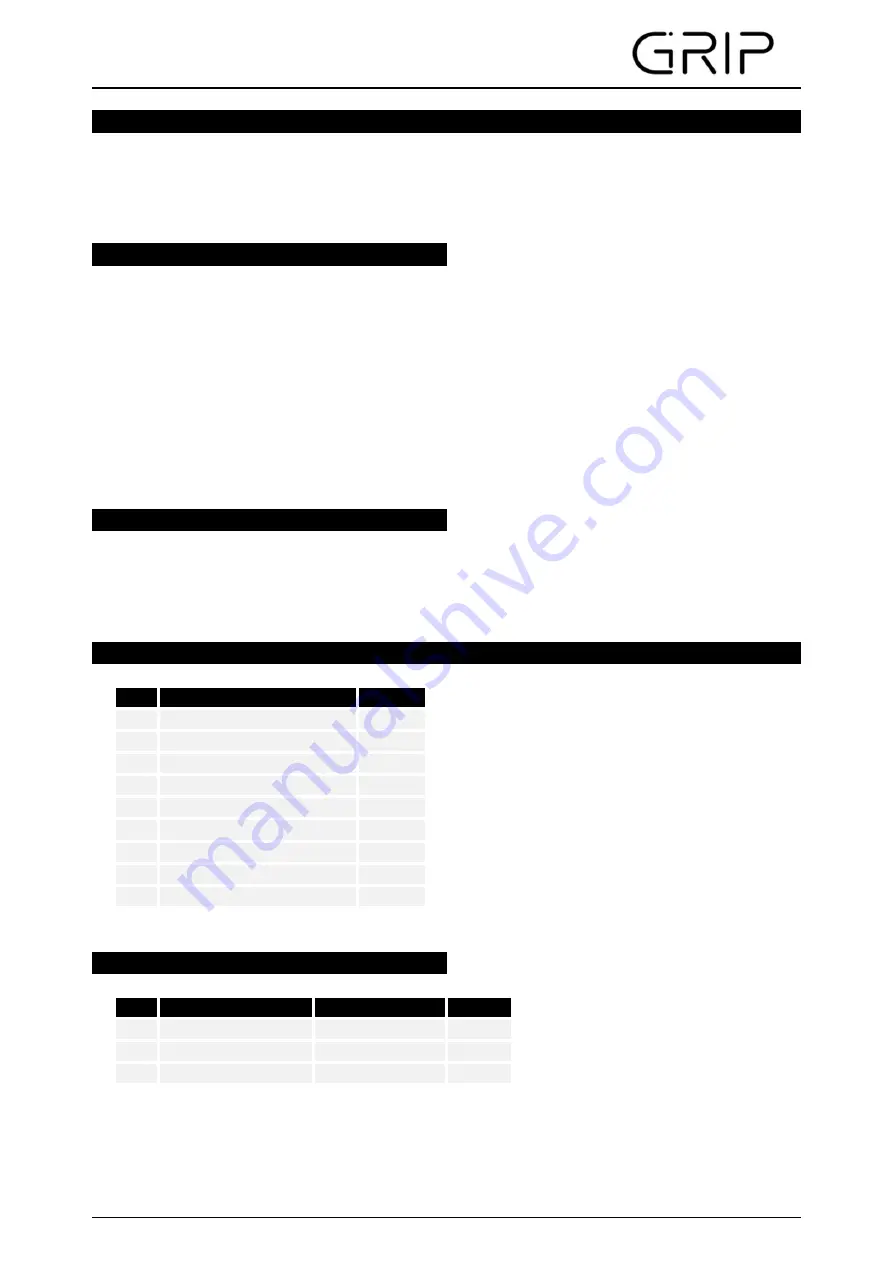

8 Parts list

8.1 Spare and wear parts

Rev. 1.01

5

The Base Connector SWS is virtually maintenance-free. Check the semi-cylindrical bolt in regular

intervals for correct function. Keep the mating surface and the moving parts clean and lubricate

them slightly.

Spare parts and component parts of the SWS can be found on our homepage:

www.grip-gmbh.com

To disassemble the semi-cylindrical bolt (Pos. 2) from the other component parts (Pos. 5,

6, 7 and 8), remove the cylinder bolt (Pos. 8).

1

2

11

Anti-rotation-protection

EG-SWS200-VS2

1

Upper assembly

2

Quantity

1

10

Square Socket Key

ZG-VKS160-SW20

6

Screw VS2

9

1

Pos. Description

1

1

7

Flap VS2

1

4

Index pin

Lower assembly SWS

Semi-cylindrical bolt

1

3

Setscrew

1

2

1

5

Housing VS2

Semi-cylindrical bolt

Order-No.

EG-SWS200-HB

Quantity

1

8

Cylinder bolt VS2

1

Pos. Description