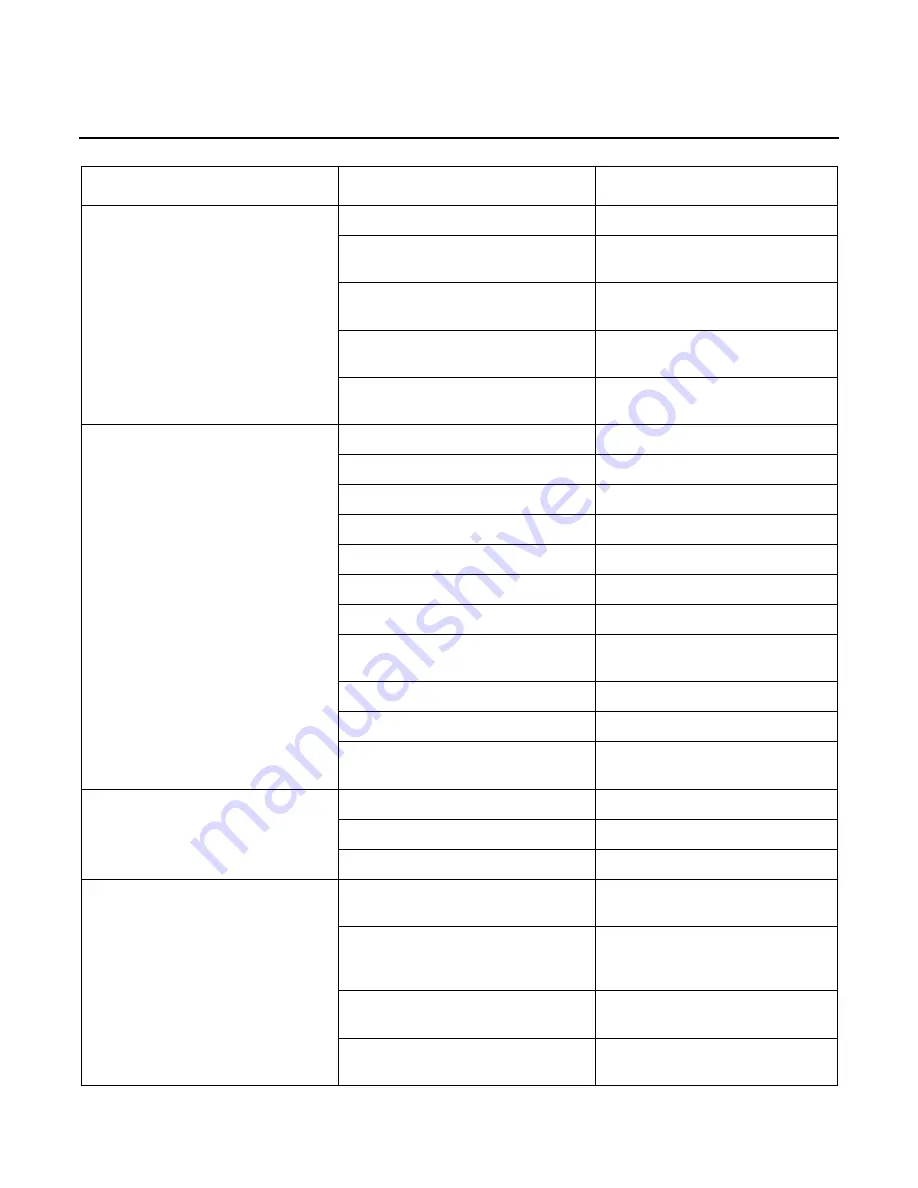

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Leaks in air system

Replace worn parts as necessary

Worn or loose drive belts

Tighten or replace belts as

necessary.

Pilot valve or pressure switch

differential adjusted too close

Have adjustments made by

authorized service location

Compressor valves not operating

properly

Replace valves

Compressor Loads/Unloads or

Starts/Stops excessively

Compressor too small for

application

Use compressor with higher air

output ratings

Clogged inlet filter

Clean or replace as necessary

Leaks in air lines, valves, or fittings

Replaces parts as necessary

Drive belts slipping

Tension belts

Drain valve left open

Close drain valve

Broken pressure gauge

Replace pressure gauge

Leaking head gasket

Replace head gasket

Dirty or plugged intercooler tubes

Remove and clean tubes

Unloader pilot or pressure switch

adjusted too low, or inoperative

Make necessary adjustments, or

replace

Worn or broken compressor valves

Replace worn parts

Worn piston or rings

Replace worn parts

Insufficient output - low

discharge pressure

Restrictive check valve

Clean check valve and replace if

necessary

Faulty unloader/check valve

Replace valve

Valves incorrectly installed Install

valves

correctly

Motor stalls

Drive belts too tight

Adjust belt tension

Cycle too short to vaporize moisture

during compression

Allow for a longer operating cycle

Compressor operating in cold

conditions - inlet filter not protected

against weather

Provide adequate protection

against extreme weather

conditions.

System pressure leaking back

through check valve

Check and replace check valve if

necessary

Water in crankcase oil - Oil gets

dirty, valves or cylinders get

rusty.

Wrong oil being used

Drain oil and replace with proper

oil

17