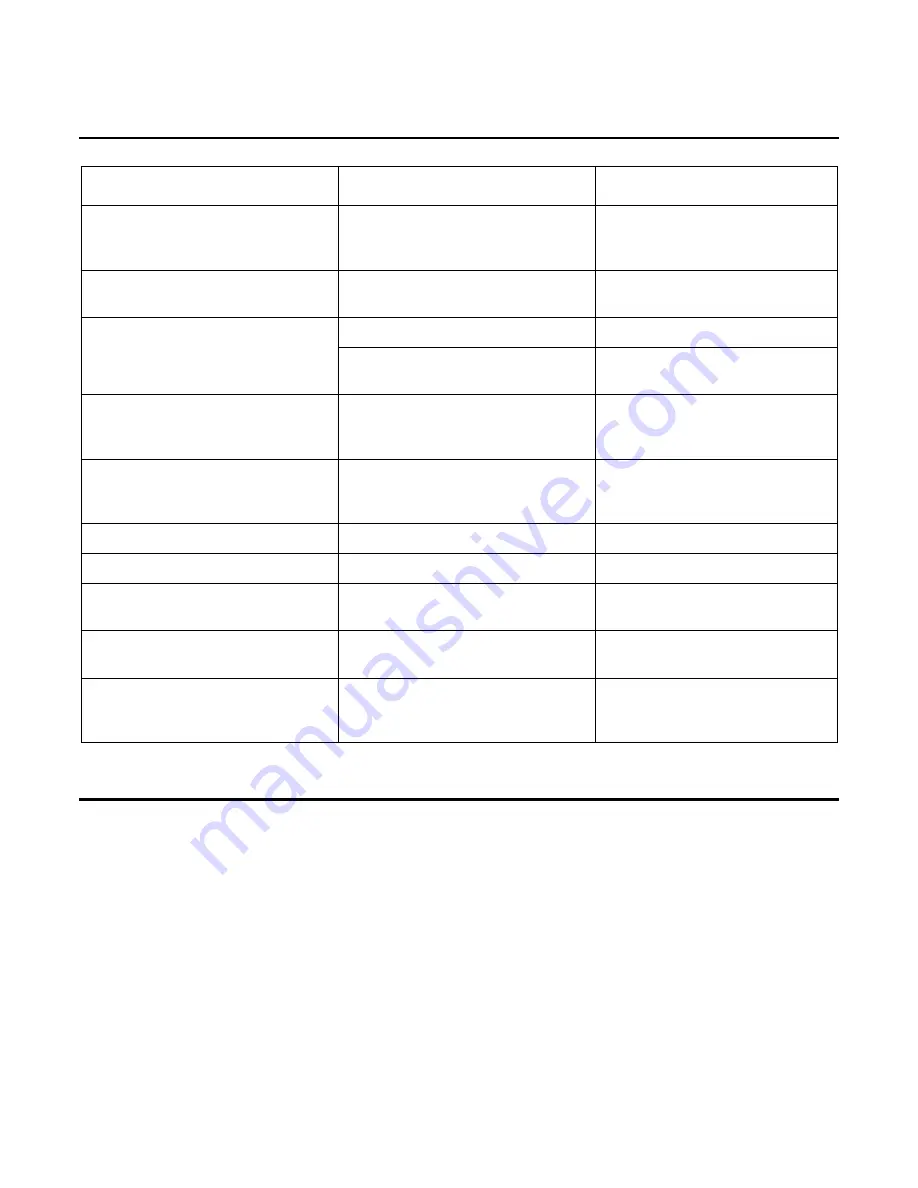

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Tool, sprayer, or other accessory

doesn't work properly.

Air pressure too low or too high

Adjust regulator to provide

pressure recommended by

product manufacturer.

Unit runs continuously

Air usage greater than compressor

output capacity

Check CFM requirements of air

tool or accessory being used.

Oil level low

Check for leaks, and add oil

Noisy operation

Internal wear or damage

Have unit serviced by authorized

service dealer.

Air leaks at motor/pressure

switch release valve while motor

is running

Switch inoperable

Have authorized service dealer

replace switch

Air leaks at motor/pressure

switch release valve after motor

stops.

Switch inoperable

Have authorized service dealer

replace switch

Air leaks at fittings

Fittings loose

Tighten fittings

Air leaks at compressor head

Head bolts loose

Tighten bolts securely

Air blows out of inlet filter

Damaged reed valve

Have unit serviced by authorized

service dealer

Crankcase oil appears milky

when dipstick is checked

Water in oil from condensation Change

crankcase

oil.

Moisture in discharge air

Excessive condensation in air tank

Drain tank more frequently. Tip

unit when draining tank to drain

all water.

STORAGE

Open tank drain valve and allow all air pressure to escape.

Drain all moisture out of tanks, and close drain valves.

Disconnect air hose and wind hose carefully for storage

Inspect compressor for wear, damage, or missing parts, and have repairs made

promptly.

Store unit in a dry, cool place.

Storage in vehicles or trailers - secure the compressor to keep it from tipping or being

damaged by contact with other equipment. Make sure gauges, fittings, and knobs are

clear of objects that could cause damage.

Do not place heavy objects on top of compressor.

19