-18-

g0555X

(Mfg. since 1/12)

figure 16. dust hose attached to dust port.

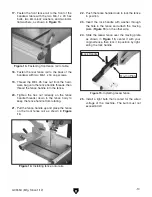

"blade tracking" is how the blade rides on the

wheels. When tracking correctly, the blade rides

in the center of both wheels.

blade tracking is primarily controlled by adjust-

ing the upper wheel tilt. tracking the blade in

this manner is referred to as "Center tracking,"

because you tilt the wheel until the blade rides in

the center.

another way to track the blade is known as

"Coplanar tracking." Coplanar tracking involves

aligning the wheels so they are parallel and

aligned. (see

Wheel Alignment on page 42.)

When wheels are coplanar, the bandsaw decreas-

es vibration and heat.

the wheels on the Model g0555X are factory

aligned, so center tracking is the only adjustment

that needs to be performed

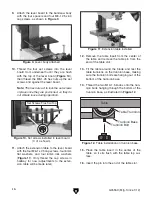

To center track the blade:

1. disConneCt bandsaW FroM poWer!

2. adjust the upper/lower guide bearings and

support bearings away from the blade.

3. open the upper wheel cover.

4. adjust the blade tension to match the size

of the installed blade with the mark on the

blade tension scale located on the back of

the bandsaw.

5. spin the upper wheel by hand at least three

times and watch how the blade rides on the

crown of the wheel. refer to

figure 17 for an

illustration of this concept.

—

If the blade rides in the center of the

upper wheel and is centered on the peak

of the wheel crown, then the bandsaw is

already tracked properly and no additional

adjustments are needed. skip to

Step 9.

—

If the blade does not ride in the center

of the upper wheel and is not centered

on the peak of the wheel crown, then

continue with the next step.

Blade Tracking

To connect a dust collection hose:

1. Fit the 4" dust hose over the dust port, as

shown in

figure 16, and secure in place with

a hose clamp.

2. tug the hose to make sure it does not come

off.

Note:

A tight fit is necessary for proper per-

formance.

Only operate the Model G0555X with an

adequate dust collection system. This saw

creates substantial amounts of fine wood

dust while operating. failure to use a dust

collection system can result in respiratory

illness.

Dust collection

Recommended cfM at Dust port: 400 cfM

Do not confuse this CFM recommendation with

the rating of the dust collector. To determine

the CFM at the dust port, you must consider

these variables: (1) CFM rating of the dust col-

lector, (2) hose type and length between the

dust collector and the machine, (3) number

of branches or wyes, and (4) amount of other

open lines throughout the system. Explaining

how to calculate these variables is beyond the

scope of this manual. Consult an expert or pur-

chase a good dust collection "how-to" book.