g0555X

(Mfg. since 1/12)

-23-

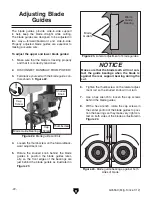

NOTICE

Whenever changing a blade or adjusting ten-

sion and tracking, the upper and lower blade

guide bearings and guide-blocks must be re-

adjusted before cutting operations.

NOTICE

The blade guides should only have light

pressure against the blade.

9. tighten the cap screws to lock the blade

guides in position.

When the blade guide bearings are properly

positioned, they rotate when the bandsaw

wheel is turned and they can be rotated with

your fingers when the blade is still.

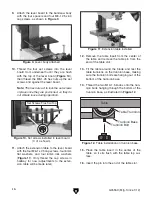

figure 25. squaring table to blade.

6. secure the plastic knobs and lock the positive

stop bolt by tightening the hex nut against the

casting.

Ensure that the bolt does not turn by

holding with another wrench while tightening

the hex nut.

an adjustable positive stop allows the table to

easily return to 90˚ after tilting.

To set the positive stop 90˚ to the blade:

1. Make sure the blade is correctly tensioned as

described in the

Tensioning Blade instruc-

tions on

page 20.

2. disConneCt bandsaW FroM poWer!

3. loosen the two plastic knobs that secure the

table to the trunnions.

4. loosen the hex nut that locks the positive

stop bolt in place.

5. raise the upper blade guide assembly and

place a 6" machinist’s square or try-square

on the table next to the side of the blade as

illustrated in

figure 25. adjust the positive

stop bolt to raise or lower the table until the

table is 90˚ to the blade.

Adjusting positive

Stop

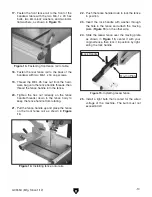

the pointer on the table tilt scale must be calibrat-

ed in order for the scale reading to be accurate.

To calibrate the pointer on the table tilt scale:

1. Make sure that the blade is tensioned and is

tracking correctly, and that the table is 90˚ to

the blade (this procedure should be already

completed with the

Adjusting positive Stop

instructions).

2. loosen the screw on the pointer so the point-

er is able to move.

3. align the tip of the pointer with the 0˚ mark on

the table tilt scale.

4. tighten the screw on the pointer so the point-

er is locked in place.

Setting Table

Tilt Scale to 0˚