g0457 14" industrial Bandsaw (Mfg. Since 5/11)

-41-

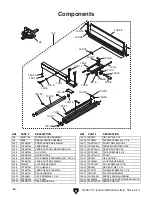

Guide post

1. diSConneCt BAndSAW FroM poWer!

2. open the upper wheel cover, then lower

the guide post so the upper guide bearings

almost touch the table.

3. Wipe the old grease off the rack (the long

plate with teeth). the old grease will be

contaminated with sawdust, so you want to

remove as much of it as possible (

figure

55).

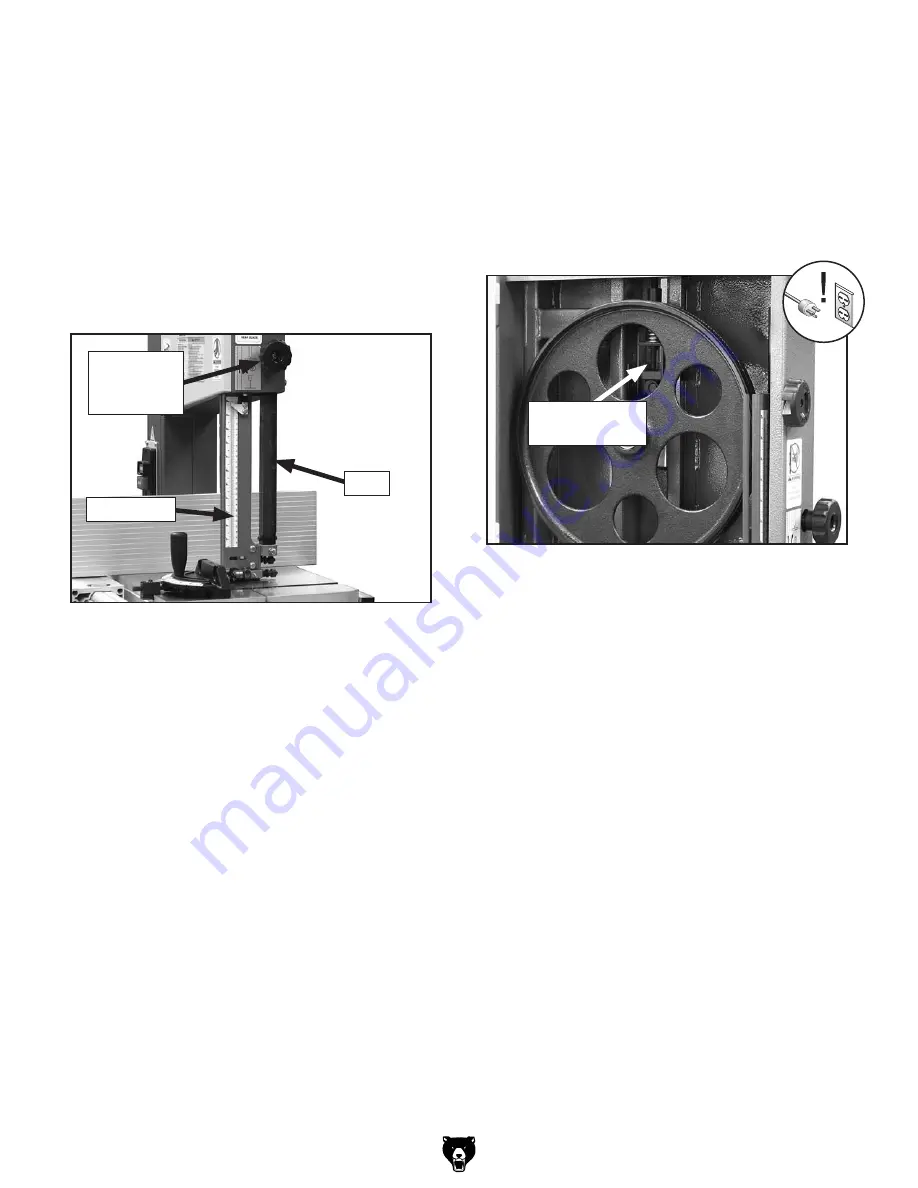

Blade Tension Leadscrew

1. diSConneCt BAndSAW FroM poWer!

2. open the upper wheel cover, then wipe as

much of the old grease off the blade tension

leadscrew as possible. the old grease will

be contaminated with sawdust, so you want

to remove as much of it as possible (

figure

35).

4. Use mineral spirits or degreaser to clean any

remaining grease from the rack. Make sure to

thoroughly wipe off the degreaser or mineral

spirits after use so they won't contaminate

the new grease.

5. Use a small, clean brush to apply nlgi#2 or

equivalent automotive-grade multi-purpose

grease to the rack. After applying, rotate the

guide adjustment knob several times to dis-

tribute the grease.

6. Close the upper wheel cover, and re-adjust

the guide post height as necessary.

figure 55.

Guide post rack lubrication.

guide post

rack

guide

Adjustment

Knob

3. Use mineral spirits or degreaser to clean any

remaining grease from the leadscrew. Make

sure to thoroughly wipe off the degreaser or

mineral spirits after use so they will not con-

taminate the new grease.

4. Use a small, clean brush to apply nlgi#2 or

equivalent automotive-grade multi-purpose

grease to the leadscrew. After applying,

rotate the blade tension knob through its full

range of motion to distribute the grease.

5. Close the upper wheel cover, and re-adjust

the blade and belt tension as necessary.

figure 56.

Blade tension leadscrew.

Blade tension

leadscrew