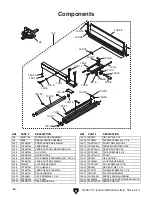

g0457 14" industrial Bandsaw (Mfg. Since 5/11)

-47-

to ensure accuracy when cutting stacked

workpieces, the table should be 90˚ to the back of

the blade as shown in

figure 61. if the table is not

perpendicular to the back of the blade, the table

needs to be shimmed.

Shims can be made of any durable object that

can be sandwiched between the table and the

trunnions. We recommend using shim washers or

shim stock because of the wide range of available

thicknesses. these items can be purchased at

your local hardware store.

figure 61. Squaring table to blade back.

To shim the table:

1. Make sure that the blade is tracking properly

and that it is correctly tensioned.

2. diSConneCt BAndSAW FroM poWer!

3. loosen the table mounting bolts that secure

the table to the trunnion.

4. place shims between the table and the trun-

nion to position the table in the desired direc-

tion.

5. Follow the Aligning Table instructions on

page 22

to complete this procedure.

Shimming Table

Blade Lead

figure 62. Blade leading away from line of cut.

Bandsaw blades sometimes wander off the cut

line when sawing, as shown in

figure 62. this is

called blade lead. Blade lead is commonly caused

by too fast of a feed rate, a dull or abused blade,

or improper tension. if your blade is sharp/undam-

aged and you still have blade lead, perform the

following instructions.

correct blade lead

1. Use less pressure when feeding the workpiece

through the cut.

2. Check that the miter slot or fence is parallel

to the blade line, and correct if necessary.

3. Check for proper blade tension. if the blade

tension is correct and it is not convenient to

replace the blade, compensate for lead by

skewing the fence or adjusting the table.

Skewing your fence

1. Cut a piece of scrap wood approximately

3

⁄

4

"

thick x 3" wide x 17" long. on a wide face of

the board, draw a straight line parallel to the

long edge.

2. Cut halfway through the board on the line by

pushing it into the blade. turn the bandsaw

OFF

and wait for the blade to stop.

Front

Back