Model G0464/G0465/G0467/G0468/G0470 Air Compressors

-

18

-

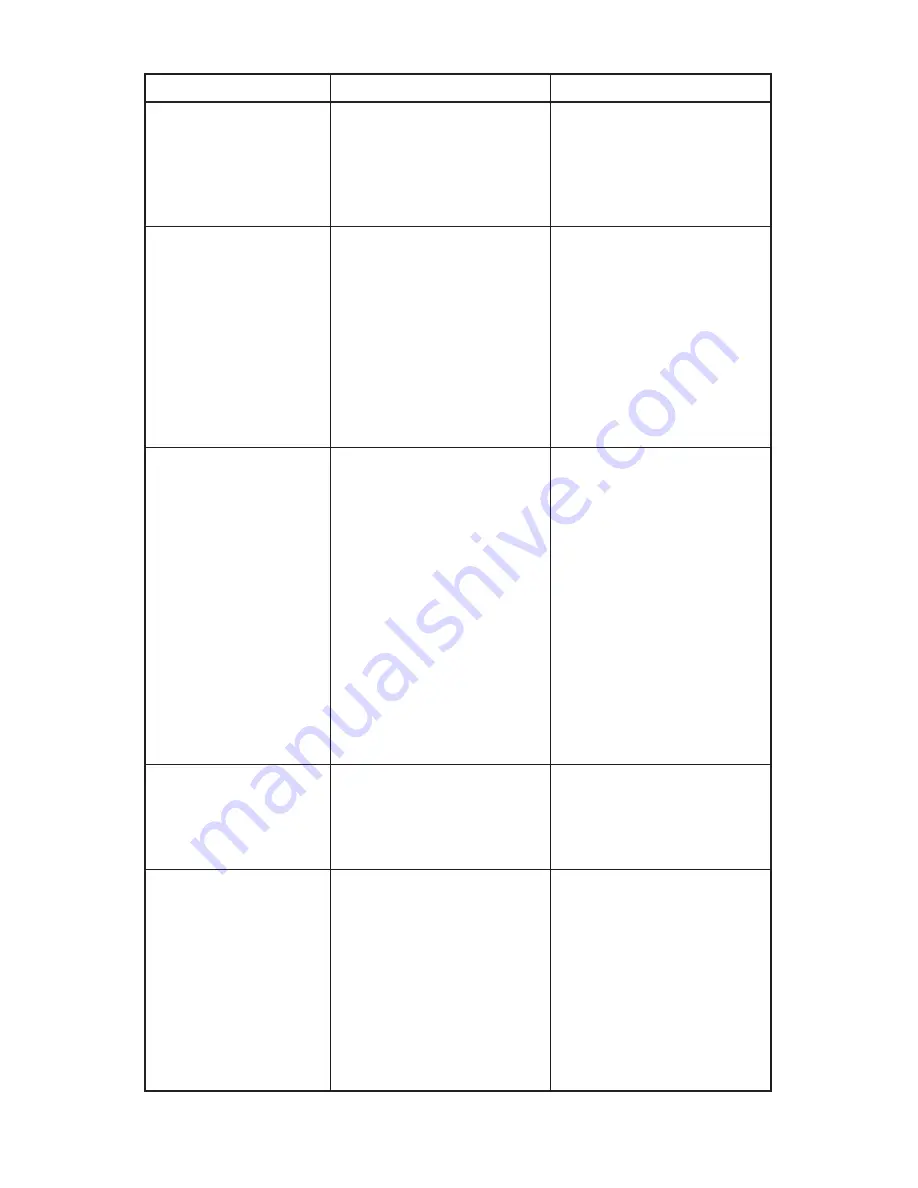

Symptom

Possible Cause

Possible Solution

Loud repetitious noise

coming from machine.

1. Pulley setscrews or keys

are missing or loose.

2. Motor fan is hitting the

cover.

1. Inspect keys and set-

screws. Replace or

tighten if necessary.

2. Adjust fan cover mounting

position, tighten fan, or

shim fan cover.

Low pressure at the

tool.

1. Pressure regulator.

2. Air leaks in hoses.

3. Pressure gauge bad.

4. Pressure switch turns the

motor

OFF

too soon.

1. Adjust pressure regulator,

if no improvement, inspect

regulator for leaks or

replace.

2. Check air hoses and all

connections for leaks (see

Page 20

).

3. Replace the pressure

gauge.

4. Adjust the pressure switch

(see

Page 21

).

Low pressure at the

tanks, or tank pressure

drops after compressor

is turned

OFF

.

1. Air leaks in tanks or deliv-

ery pipes.

2. Drain valve open.

3. Air filter clogged.

4. Leaking check valve.

5. Pressure relief valve

releasing below 120 PSI.

6. Gaskets leaking.

7. Worn rings.

8. Pressure switch turns the

motor

OFF

too soon.

1. Check air tanks, pipes and

all connections for leaks

(see

Page 20

).

2. Close drain valve.

3. Inspect and clean air filter.

4. Repair the check valve

(see

Page 19

).

5. Replace pressure relief

valve.

6. Check gaskets on cylinder

head assembly, repair or

replace as needed.

7. Inspect and replace pump

piston rings.

8. Adjust the pressure switch

(see

Page 21

).

Compressor knocking.

1. Improper oil level.

2. Air filter clogged.

3. Piston assembly loose.

1. Check oil level and add oil

(see

Page 9

).

2. Inspect and clean air filter.

3. Inspect and repair piston

and connecting rod.

Pressure relief valve

stays open and motor

won’t stop running.

1. Pressure switch adjusted

too high.

2. Faulty pressure switch,

unit is trying to overpres-

sure the tank.

3. Faulty pressure relief

valve.

1. Adjust the pressure switch

(see

Page 21

)

2. Turn compressor

OFF

,

unplug from power sup-

ply, and empty tank.

DO NOT USE until switch

is replaced.

3. Relief valve is reliev-

ing pressure too early.

Replace pressure relief

valve.

Summary of Contents for G0464

Page 2: ......

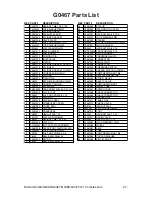

Page 24: ...Model G0464 G0465 G0467 G0468 G0470 Air Compressors 22 G0464 Parts Breakdown ...

Page 26: ...Model G0464 G0465 G0467 G0468 G0470 Air Compressors 24 G0465 Parts Breakdown ...

Page 28: ...Model G0464 G0465 G0467 G0468 G0470 Air Compressors 26 G0467 Parts Breakdown ...

Page 30: ...Model G0464 G0465 G0467 G0468 G0470 Air Compressors 28 G0468 Parts Breakdown ...

Page 32: ...Model G0464 G0465 G0467 G0468 G0470 Air Compressors 30 G0470 Parts Breakdown ...