-16-

Model g0493 (Mfg. since 7/10)

extension cords

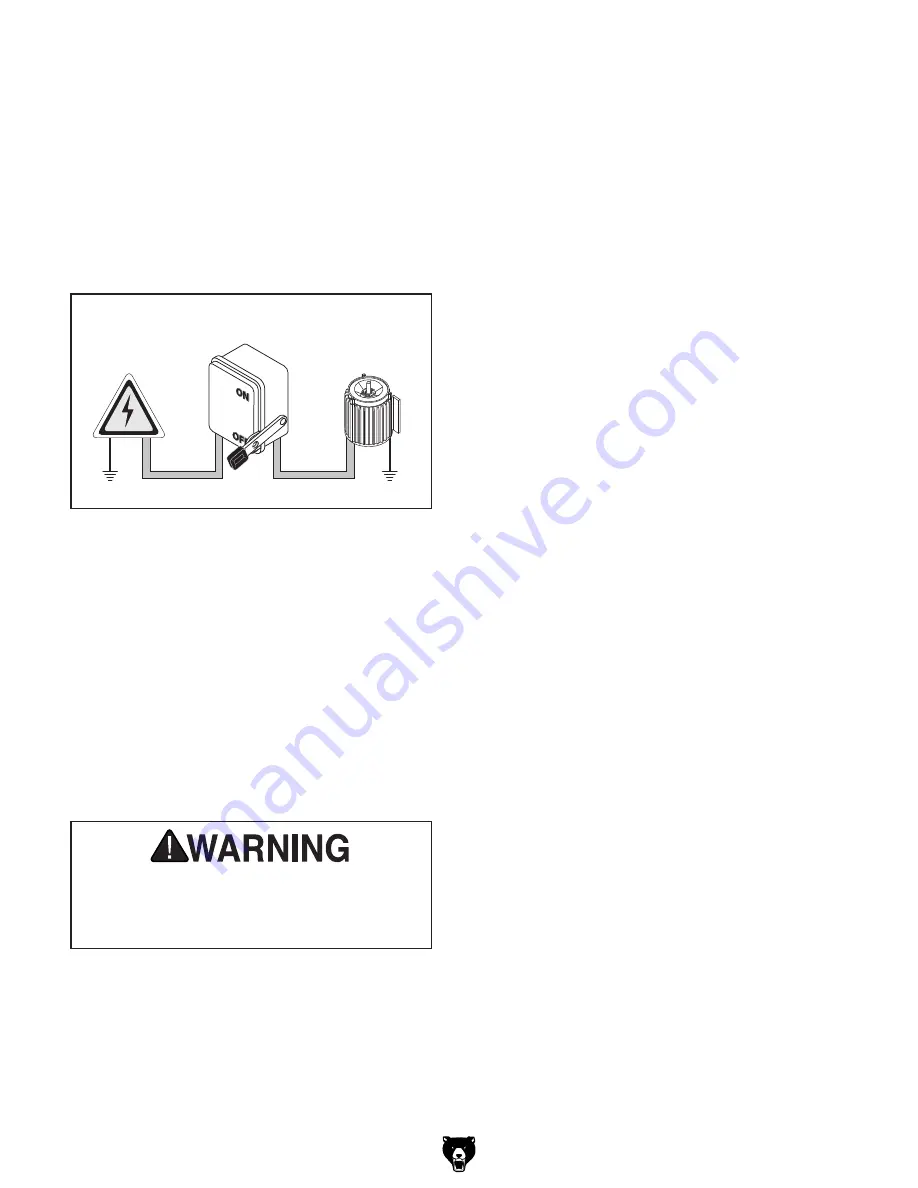

Since this machine must be permanently con-

nected to the power supply, an extension cord

cannot be used.

connection type

figure 6. typical setup of a permanently

connected machine.

Power

Source

Locking

Disconnect Switch

Machine

Ground

Ground

Conduit

Conduit

A power cord is not included, because this

machine must be permanently connected to the

power supply. A disconnecting means, such as

a locking switch (see

Figure

below), must be

provided to allow the machine to be disconnected

(isolated) from the power supply when required.

This installation must be performed by a qualified

electrician in accordance with all applicable elec-

trical codes and ordinances.

Serious injury could occur if you connect

the machine to power before completing the

setup process. DO NOT connect to power

until instructed later in this manual.

grounding instructions

In the event of a malfunction or breakdown,

grounding provides a path of least resistance

for electrical current to reduce the risk of electric

shock. A permanently connected machine must

be connected to a grounded metal permanent wir-

ing system; or to a system having an equipment-

grounding conductor. All grounds must be verified

and rated for the electrical requirements of the

machine. Improper grounding can increase the

risk of electric shock!

phase converter

When using a phase converter, the power from

the manufactured power leg (sometimes called

the wild wire) can fluctuate. Connect the manu-

factured power leg to the s terminal to prevent

damage to the transformer. the wire from the s

terminal can handle some fluctuation because it

goes directly to the motor. the power going to the

r and t terminals goes to the transformer and

must be consistent to prevent damage.