-6-

G0516 Lathe/Mill

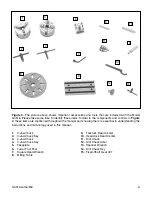

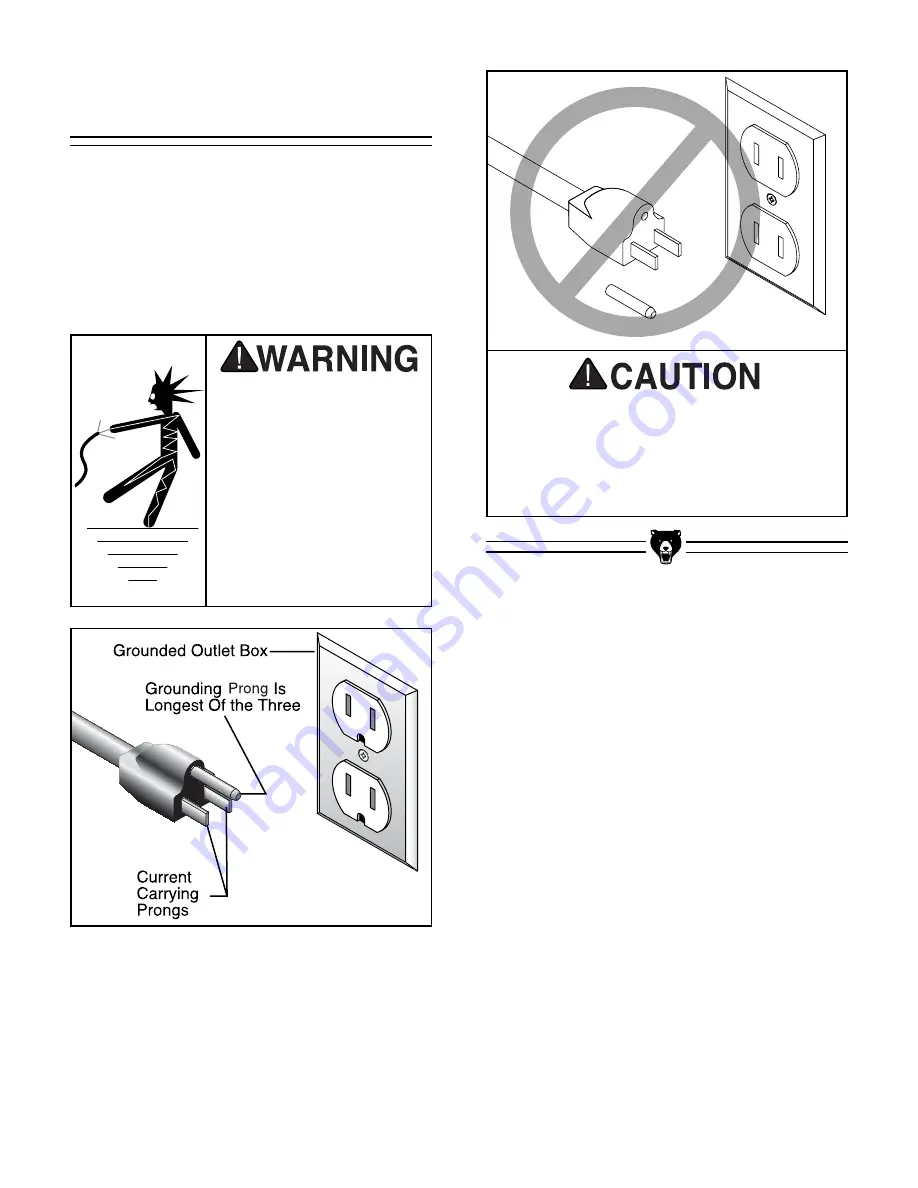

Figure 1.

Typical 110V plug and outlet.

Grounding

In the event of an electrical short, grounding

reduces the risk of electric shock by providing a

path of least resistance to disperse electric cur-

rent. This tool is equipped with a power cord hav-

ing an equipment-grounding prong.

See Figure

1.

The outlet must be properly installed and

grounded in accordance with all local codes and

ordinances.

This machine must have a ground prong in

the plug to help ensure that it is grounded.

DO NOT remove ground prong from plug to

fit into a two-pronged outlet! If the plug will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

Verify that any existing

electrical outlet and cir-

cuit you use is actually

grounded. If not, it will be

necessary to run a sepa-

rate 12 A.W.G. copper

grounding wire from the

outlet to a known ground.

If not grounded properly,

serious personal injury

could occur.