g0529 oscillating Spindle & disc Sander

-19-

disc sanding

to perform disc sanding operations:

1.

Set the angle of the table relative to the

sanding disc. the angle can be set with the

angle gauge on the disc sander or with a

protractor for greater accuracy.

note—

The disc table can be positioned from

0˚ to 45˚, relative to the plane of the sanding

surface.

2.

once the desired table angle has been set,

move the table towards the sanding disc to

decrease the gap between the table and the

disc. the gap should be

1

⁄

16

".

3.

to sand straight edges, firmly hold the side

of workpiece against the miter gauge (set at

0˚), with the other surface against the face of

the disc (

figure 18

).

note—

For sanding curves or irregular

shapes, remove the miter gauge from the

disc table. Always keep the workpiece on the

side of the wheel that is rotating down toward

the table. This will keep the workpiece from

flying out of your hands from the rotational

forces.

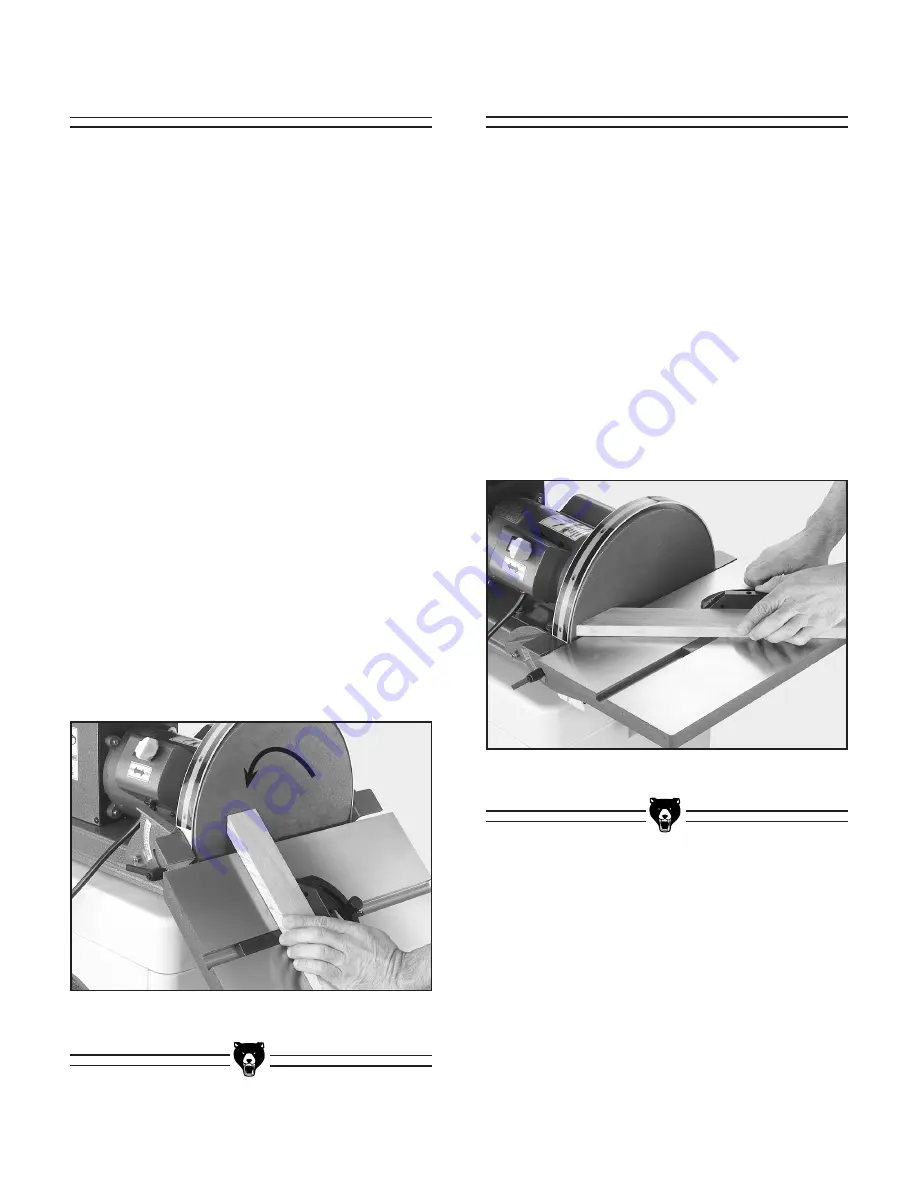

miter sanding

the most efficient way to get a perfect miter is to

cut the workpiece slightly long and sand it to the

desired dimension. Miter sanding can be done

easily with the miter gauge:

to perform miter sanding operations:

1.

loosen the knob on the miter gauge, adjust

the angle to the desired point, and tighten the

knob.

2.

Slide the miter gauge into its slot and use it

to hold your workpiece in position (

figure

19

). note—

The miter gauge can be used in

either direction in the slot to achieve the

proper relation of the workpiece to the disc.

figure 19

. disc sanding with table tilted.

figure 20

. disc sanding with miter.