-30-

g0529 oscillating Spindle & disc Sander

machine operation continued

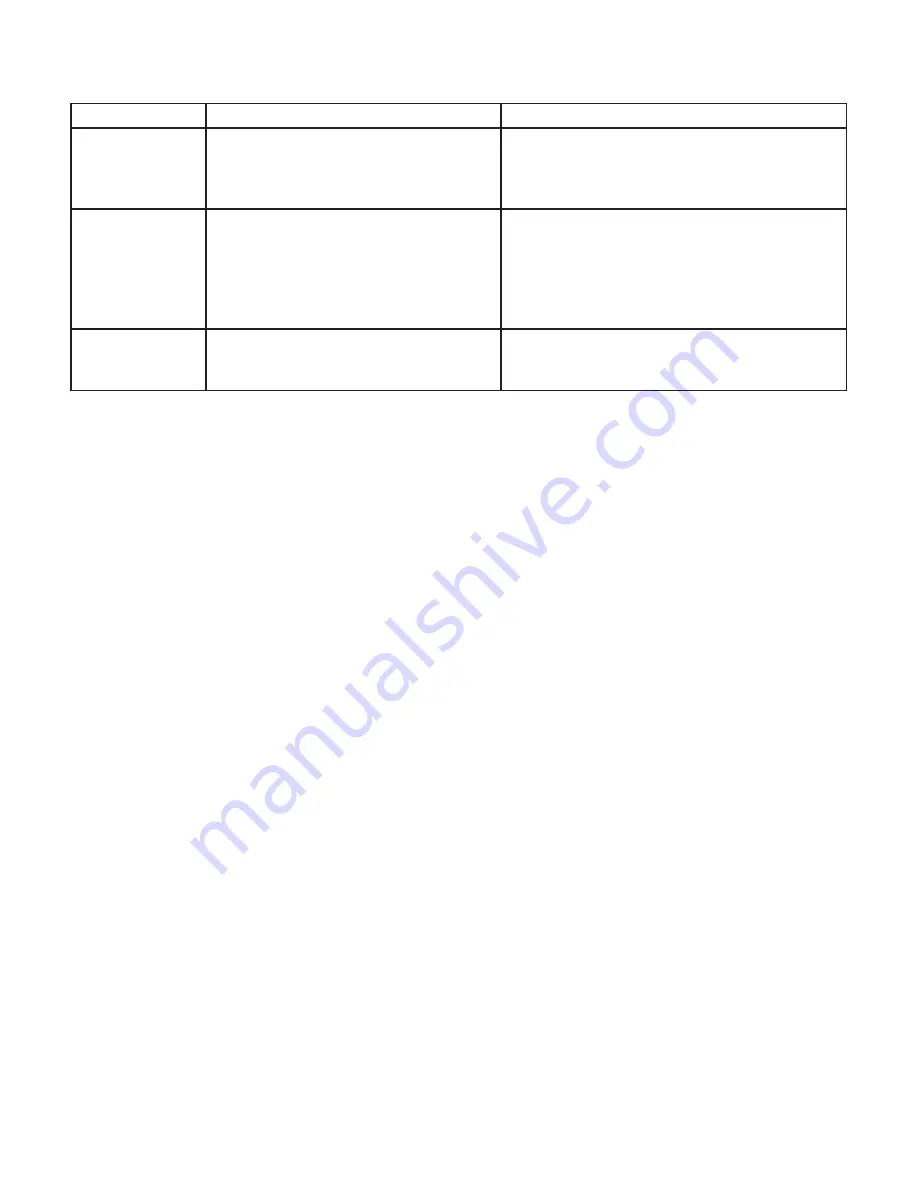

Symptom

possible Cause

possible Solution

Machine

slows

when

operating.

1. applying too much pressure to workpiece.

2. undersized circuit or using ext cord.

1. Sand with less pressure—let the movement of the

sleeve/disc do the work.

2. Make sure circuit wires are proper gauge & don’t use

ext cords!

Machine vibrates

excessively.

1. Stand not stable on floor.

2. incorrect motor mounting.

3. incorrect sanding sleeve tension.

4. Broken/defective sanding sleeve/disc.

1. Secure stand to floor, reposition to level surface, or

shim stand.

2. Check/adjust motor mounting.

3. Make sure tension lever is in tensioning position.

Follow sleeve tensioning instructions in this manual.

4. replace sanding sleeve/disc.

Workpiece frequent-

ly gets pulled out of

your hand.

1. not supporting the workpiece against the

stop.

2. Starting the workpiece on a leading corner.

1. use back stop to support workpiece.

2. Start workpiece on a trailing corner.