G0532 2HP Dry Spray Booth

-19-

Air Filter Indicator

Components and Hardware Needed:

Qty

Air Filter Indicator (Manometer) ..........................1

Tubing Connector Fitting ....................................1

Tubing .................................................................2

Plastic Clip ..........................................................1

Tap Screw M4 x 12 .............................................1

Tap Screws M4 x 45 ...........................................2

To install the air filter indicator:

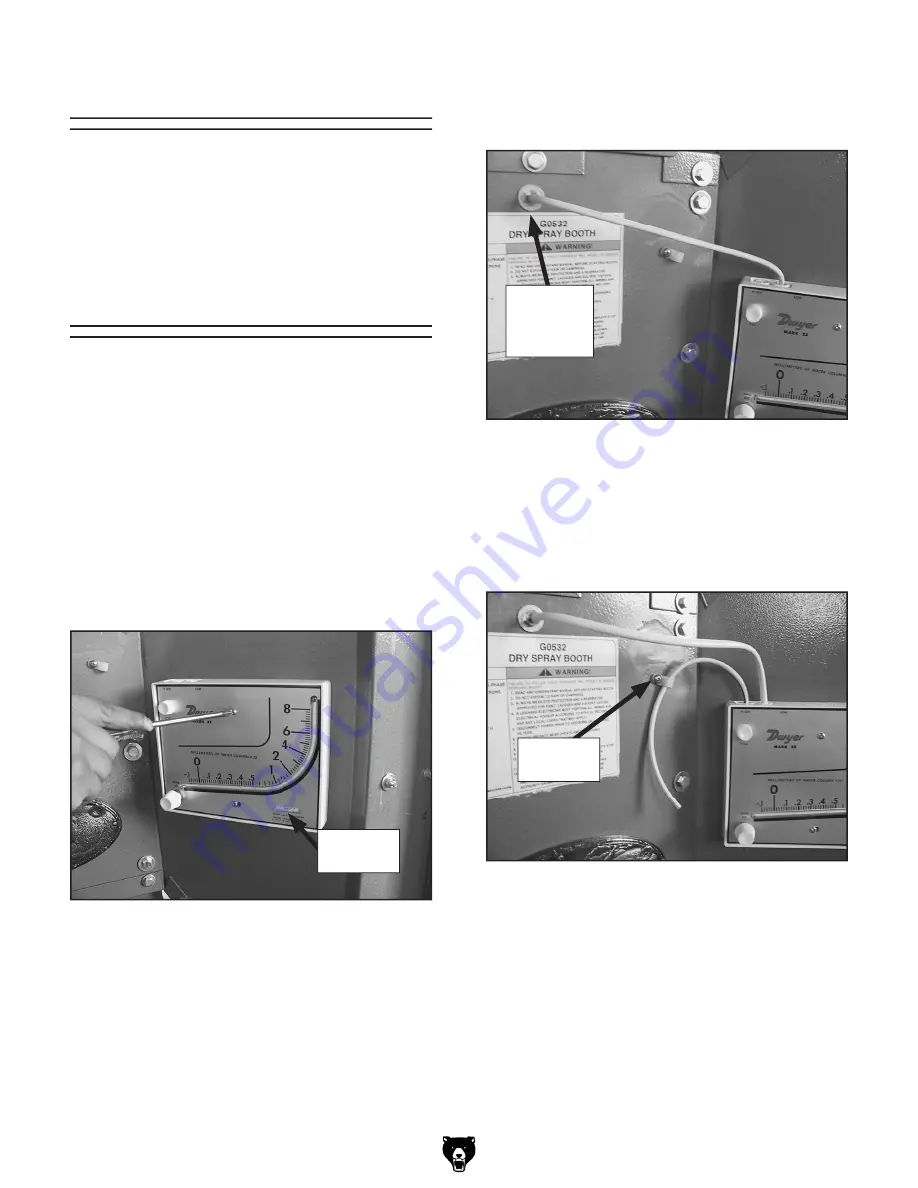

1.

Mount the manometer to the side of the

spray booth using the M4 x 45 tap screws as

shown in

Figure 21

.

5.

Install tubing onto the high pressure side (+)

of the manometer and secure it with the plas-

tic clip and M4 x 12 tap screw as shown in

Figure 23

.

Figure 22.

Tubing installed onto spray booth

chamber.

2.

Adjust the manometer so the built-in level

reads level (

Figure 21

).

3.

Install a tubing connector fitting in the larger

pre-drilled hole on the side of the booth near

the manometer as shown in

Figure 22

.

4.

Run tubing from the low pressure side (-) of

the manometer to the tubing connector fitting

as shown in

Figure 22

.

Figure 21.

Mounting manometer to spray booth.

Figure 23.

Tubing secured with clip.

Ducting

The G0532 dry spray booth must be vented to

the outside of your shop or building using 10"

metal spiral wound ducting or 18 gauge rolled

galvanized steel ducts in accordance with NFPA

33 guidelines.

Tubing

Connector

Fitting

Plastic

Clip

Built-in

Level

Summary of Contents for G0532

Page 5: ...G0532 2HP Dry Spray Booth 3 Data Sheet ...

Page 6: ... 4 G0532 2HP Dry Spray Booth ...

Page 14: ... 12 G0532 2HP Dry Spray Booth Hardware Recognition Chart ...

Page 26: ... 24 G0532 2HP Dry Spray Booth 115V Wiring Diagram ...

Page 27: ...G0532 2HP Dry Spray Booth 25 230V Wiring Diagram ...

Page 28: ... 26 G0532 2HP Dry Spray Booth Parts Breakdown ...

Page 32: ... 30 G0532 2HP Dry Spray Booth ...

Page 35: ......