-26-

Model G0580 (Mfd. Since 11/06)

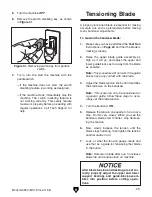

Adjusting Support

Bearings

Figure 32. Support bearing controls.

The support bearings are positioned behind the

blade and support the back of the blade dur-

ing cutting operations. Proper adjustment of the

support bearings is an important part of making

accurate cuts and also keeps the blade teeth from

coming in contact with the guide bearings while

cutting.

Tools Needed:

Qty

Wrench 10mm ....................................................1

Feeler Gauge 0.016" ...........................................1

To adjust the support bearings:

1. Make sure that the blade is tracking properly

and that it is correctly tensioned.

2. DISCONNECT BANDSAW FROM POWER!

3. Familiarize yourself with the support bearing

controls shown in

Figure 32.

4. Loosen the assembly lock bolt.

Support

Bearing Lock

Bolt

Assembly

Lock Bolt

Support

Bearing

6. Tighten the assembly lock bolt.

7. Loosen the support bearing lock bolt on the

support bearing adjustment shaft.

8. Using the feeler gauge, slide the support

bearing approximately 0.016" away from the

back of the blade, as illustrated in

Figure 34.

Figure 33. Blade should be perpendicular (90˚)

to the face of the support bearing.

Bandsaw

Blade

Support

Bearing

Top View

0.016''

Figure 34. Blade should be aligned approxi-

mately 0.016" away from the bearing edge.

Side View

5. Look at the face of the support bearing and

rotate the blade guide assembly side-to-

side, until the blade is perpendicular with the

face of the support bearing, as illustrated in

Figure 33.

Summary of Contents for G0580

Page 15: ...Model G0580 Mfd Since 11 06 13 Hardware Recognition Chart...

Page 64: ......