-28-

Model G0580 (Mfd. Since 11/06)

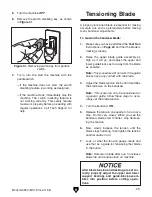

The pointer on the table tilt scale must be calibrat-

ed in order for the scale reading to be accurate.

Tools

Needed: Qty

Phillips Screwdriver ........................................... 1

To calibrate the pointer on the table tilt scale:

1. Make sure that the blade is tensioned and is

tracking correctly, and that the table is 90˚ to

the blade.

2. Loosen the screw on the pointer (see Figure

38), but do not remove it.

Figure 37. Lateral adjustment of blade guides.

Blade

Gullet

1

/

16

"

Blade

Guide

Block

6. Tighten the thumbscrew on the adjustment

rod.

7. Loosen the thumbscrews that secure the

guide blocks.

8. Adjust the position of the blocks 0.004" away

from the blade.

Note: 0.004" is approximately the thickness

of a piece of paper.

9. Tighten the thumbscrews.

Whenever changing a blade or adjusting

tension and tracking, the upper and lower

blade support bearings and guide-blocks

must be properly adjusted before cutting

operations.

Make sure that the blade teeth will not

contact the guide blocks when the blade is

against the rear support bearing during the

cut.

Calibrating Table Tilt

Scale

Figure 38. Table tilt scale location.

3. Align the tip of the pointer with the 0˚ mark on

the table tilt scale.

4. Tighten the screw on the pointer so that the

pointer is locked in place.

5. Move the guides forward or backward to posi-

tion them laterally, so that the edges of the

blocks are

1

/

16

" behind the blade gullets, as

illustrated in

Figure 37.

Summary of Contents for G0580

Page 15: ...Model G0580 Mfd Since 11 06 13 Hardware Recognition Chart...

Page 64: ......