Model G0580 (Mfd. Since 11/06)

-49-

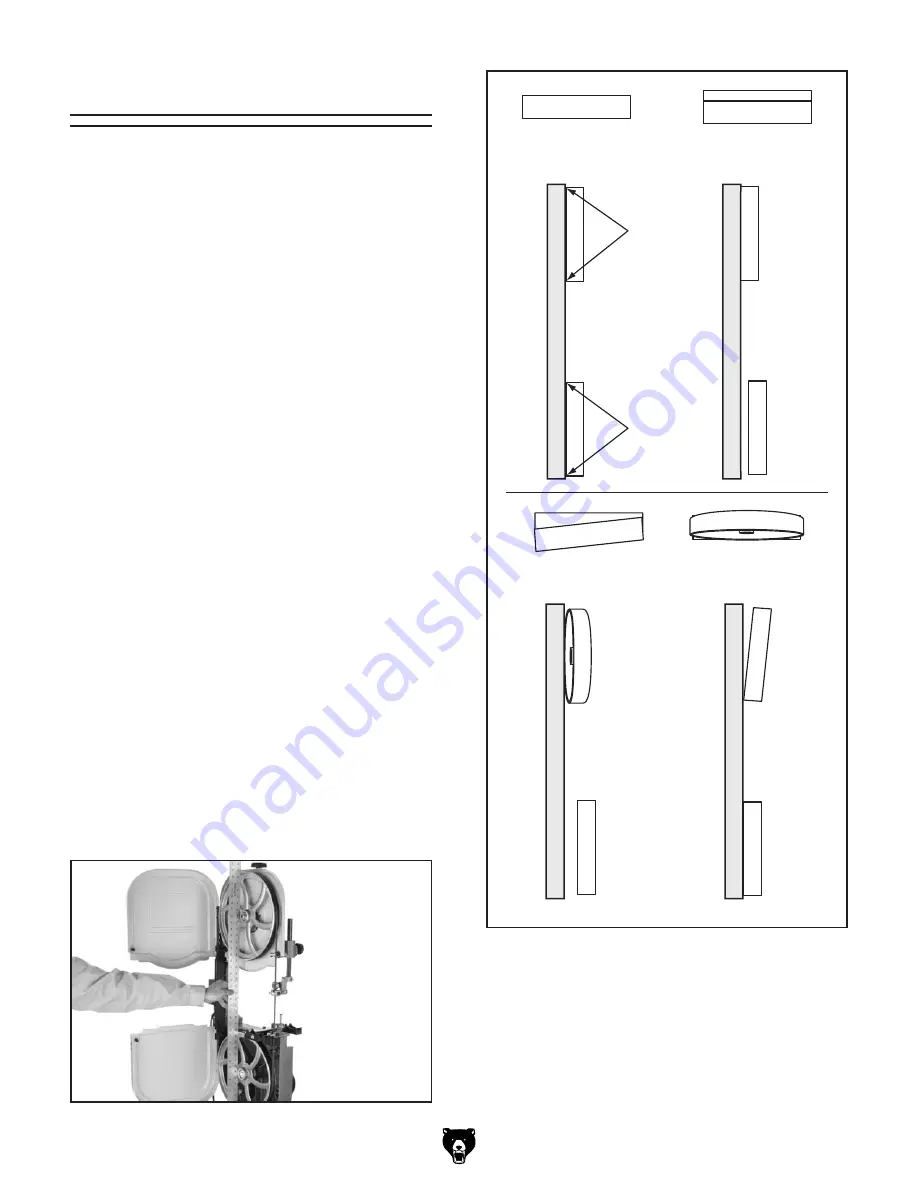

Wheel Alignment

Wheel alignment is one of the most critical fac-

tors for optimal performance from your bandsaw.

Wheels are properly aligned when they are par-

allel with each other and in the same plane or

“coplanar” (see the illustration in the figure to the

right).

Heat, vibration, wandering, blade wear, tire wear

and overall bandsaw wear are considerably

decreased when the wheels are parallel and

coplanar. Additionally, wheels that are parallel and

coplanar automatically track the blade by balanc-

ing it on the crown of the wheel—this is known as

“coplanar tracking.”

Bringing the wheel into alignment may require

a combination of shimming a wheel and center/

lateral tracking the upper blade.

Tools Needed

Qty

Straightedge 4 ft. ............................................... 1

Fine Ruler .......................................................... 1

Wrench or Socket 13mm ................................... 1

Wrench or Socket 19mm ................................... 1

Checking Wheel Alignment

1. DISCONNECT BANDSAW FROM POWER!

2. Remove the table.

3. With the blade on and properly tensioned,

hold a straightedge close to the center of

both wheels. Make sure the straightedge fully

extends across the rims of both wheels, as

shown in the figure below.

Coplanar

Parallel, Not

Coplanar

Not Parallel

Not Coplanar

Straightedge

Contacts Top

And Bottom of

Both Wheels

Straightedge

Not Parallel

Not Coplanar

Adjust

Tracking

Shim

Wheel

Figure 62. Wheel alignment illustration.

Figure 61. Checking if the wheels are coplanar.

Summary of Contents for G0580

Page 15: ...Model G0580 Mfd Since 11 06 13 Hardware Recognition Chart...

Page 64: ......