G0600 20" x 60" Big Bore Lathe

-23-

Apron and Spindle

Break-in

It is essential to closely follow the proper break-in

procedures to ensure trouble free performance.

Complete this process once you have familiarized

yourself with all instructions in this manual and

completed the test run.

To break-in the spindle:

1.

Make sure that the headstock, gearbox,

apron, and lead screw and feed rod oil bath

oil levels show full. Follow all lubrication

procedures highlighted in

Lubrication

in the

MAINTENANCE

section on

Page 51

of this

manual.

2.

Make sure there are no obstructions around

or underneath the chuck and that the chuck

is secured to the spindle. Refer to

Chuck and

Faceplate Mounting

on

Page 24

.

3.

Set the spindle speed to the lowest RPM;

refer to section

Setting RPM

on

Page 35

.

4.

Move the headstock and gearbox levers so

the feedrod and leadscrew are engaged.

Refer to section

Using the Thread Cart

on

Page 40

for lever combinations.

5.

Make sure that the halfnut lever is disen-

gaged, and that the apron and cross feed

feed lever is in neutral. Refer to section

Power Feed

on

Page 37

for lever combina-

tions.

6.

Turn the lathe

ON

and let it run for a minimum

of 10 minutes.

7.

Turn the lathe

OFF

, shift the levers to the

next highest RPM and repeat

Steps 5-6

for

each RPM setting in both directions. DO NOT

LEAVE THE AREA!

Failure to follow beak-in procedures will

likely cause rapid deterioration of bearings

and other related parts.

NOTICE

Spindle Balancing

After the spindle has been broken in, or if the lathe

has been used for a considerable amount of time,

you should adjust the spindle weights to minimize

spindle vibration.

To minimize spindle vibration:

1.

Run the lathe for five minutes on the fastest

RPM.

2.

DISCONNECT LATHE FROM POWER!

3.

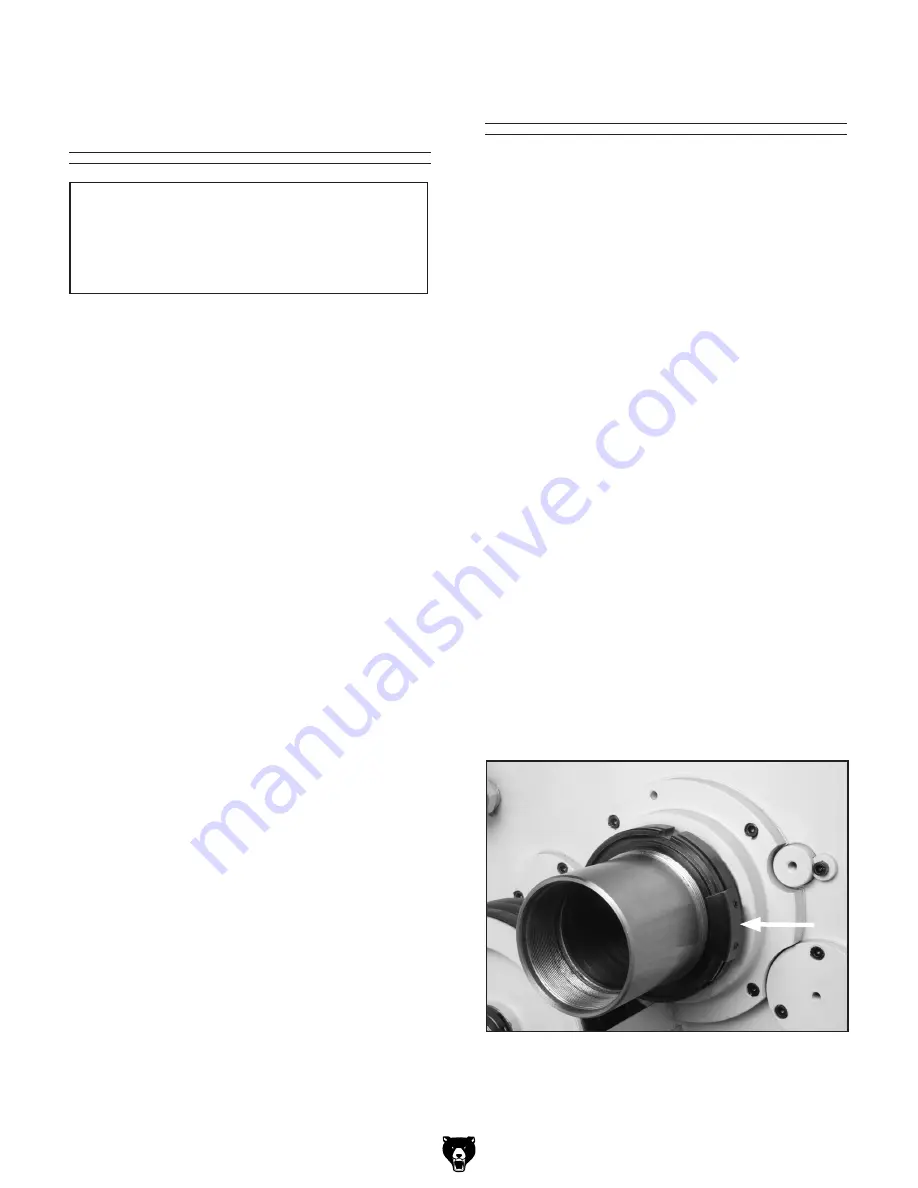

Open the side cover, loosen the counter

weight set screws (

Figure 14

), and reposition

one or both counterweights to a new posi-

tion around the circumference of the spanner

nut.

4.

Close the side cover, reconnect to power,

restart the lathe, and run at 1600 RPM.

5.

Place your hand on the headstock cover and

feel for harmonic vibration.

6.

Repeat

Steps 2

through

5

until any vibration

is reduced to its minimum.

7.

Now, repeat

Steps 2

through

5

at 1100 RPM

until any vibration is reduced to its minimum.

Figure 14

. Spindle counterweights.

Summary of Contents for G0600

Page 3: ... ...

Page 8: ...G0600 20 x 60 Big Bore Lathe 5 ...

Page 9: ... 6 G0600 20 x 60 Big Bore Lathe ...

Page 12: ...G0600 20 x 60 Big Bore Lathe 9 SECTION 1 SAFETY ...

Page 13: ... 10 G0600 20 x 60 Big Bore Lathe ...

Page 19: ... 16 G0600 20 x 60 Big Bore Lathe Hardware Recognition Chart ...

Page 72: ...G0600 20 x 60 Big Bore Lathe 69 Headstock Face and Shift System 0000 Series Parts ...

Page 73: ... 70 G0600 20 x 60 Big Bore Lathe Headstock Shift System 0000 Series Parts ...

Page 74: ...G0600 20 x 60 Big Bore Lathe 71 Headstock Oil Pump System 0000 Series Parts ...

Page 78: ...G0600 20 x 60 Big Bore Lathe 75 Quick Change Gearbox Gear System 1000 Series Series Parts ...

Page 79: ... 76 G0600 20 x 60 Big Bore Lathe Quick Change Gearbox Face 1000 Series Parts ...

Page 80: ...G0600 20 x 60 Big Bore Lathe 77 Quick Change Gearbox Shift System 1000 Series Parts ...

Page 81: ... 78 G0600 20 x 60 Big Bore Lathe Quick Change Gearbox Shift System 1000 Series Parts ...

Page 84: ...G0600 20 x 60 Big Bore Lathe 81 Carriage 2000 Series Parts ...

Page 85: ... 82 G0600 20 x 60 Big Bore Lathe Cross Slide and Carriage 2000 Series Parts ...

Page 86: ...G0600 20 x 60 Big Bore Lathe 83 Compound Rest and Tool Post 2000 Series Parts ...

Page 87: ... 84 G0600 20 x 60 Big Bore Lathe Carriage Oil Pump System 2000 Series Parts ...

Page 90: ...G0600 20 x 60 Big Bore Lathe 87 Apron Face Thread Dial Auto Stop System 3000 Series Parts ...

Page 91: ... 88 G0600 20 x 60 Big Bore Lathe Apron Gearing Halfnut Feed System 3000 Series Parts ...

Page 92: ...G0600 20 x 60 Big Bore Lathe 89 Apron Feed Rod Clutch and Lever System 3000 Series Parts ...

Page 95: ... 92 G0600 20 x 60 Big Bore Lathe Tailstock 4000 Series Parts ...

Page 97: ... 94 G0600 20 x 60 Big Bore Lathe Bed Assembly 5000 Series Parts ...

Page 98: ...G0600 20 x 60 Big Bore Lathe 95 Brake Pedal and Headstock Panels 5000 Series Parts ...

Page 99: ... 96 G0600 20 x 60 Big Bore Lathe Brake System and Change Gears 5000 Series Parts ...

Page 100: ...G0600 20 x 60 Big Bore Lathe 97 Motor and Headstock Mounting 5000 Series Parts ...

Page 101: ... 98 G0600 20 x 60 Big Bore Lathe End Covers and Splash Guard 5000 Series Parts ...

Page 102: ...G0600 20 x 60 Big Bore Lathe 99 Change Gear System 5000 Series Parts ...

Page 105: ... 102 G0600 20 x 60 Big Bore Lathe Steady and Follow Rests 6000 Series Parts ...

Page 110: ... ...

Page 111: ... ...

Page 112: ......

Page 113: ... ...