G0600 20" x 60" Big Bore Lathe

-57-

Review the troubleshooting and procedures in this section to fix your machine if a problem develops. If you

need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support

at (570) 546-9663.

SECTION 7: SERVICE

Troubleshooting

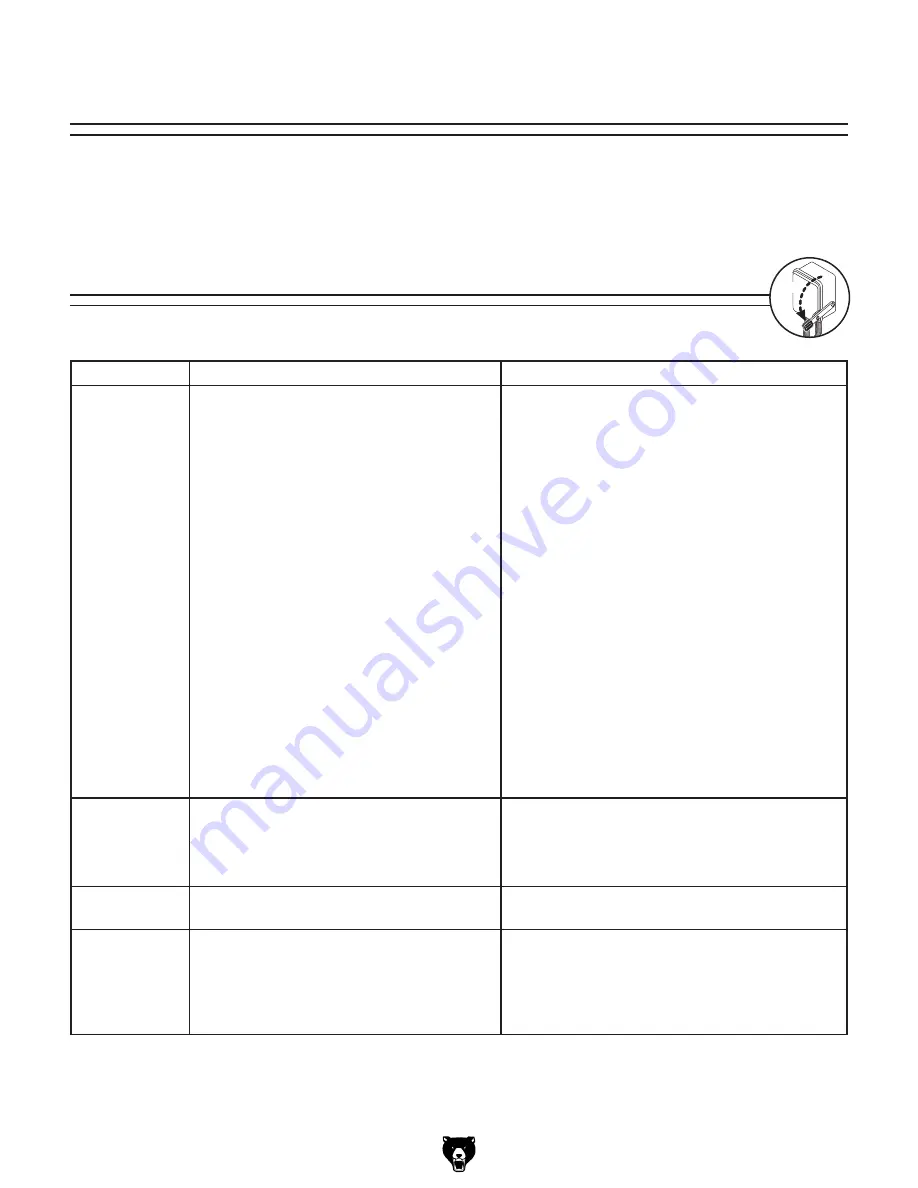

Motor & Electrical

Symptom

Possible Cause

Possible Solution

Machine does not

start or a circuit

breaker trips.

1. Foot brake is engaged.

2. Emergency stop push-button is engaged/

faulty.

3. Power supply is at fault/switched OFF.

4. Fuse has blown.

5. Plug/receptacle is at fault or wired incorrectly.

6. Start capacitor is at fault.

7. Motor connection wired incorrectly.

8. Thermal overload relay has tripped.

9. Contactor not getting energized/has burnt con-

tacts.

10. Wall fuse/circuit breaker is blown/tripped.

11. Motor ON button or ON/OFF switch is at fault.

12. Wiring is open/has high resistance.

13. Motor is at fault.

14. Spindle rotation switch is at fault.

15. Foot brake safety switch is faulty.

1. Check to see that foot brake is up.

2. Rotate clockwise slightly until it pops out/replace it.

3. Power supply is at fault/switched OFF.

4. Correct short/replace fuse in main electrical box.

5. Test for good contacts; correct the wiring.

6. Test/replace if faulty.

7. Correct motor wiring connections.

8. Turn cut-out dial to increase working amps and push

the reset pin. Replace if tripped multiple times (weak

relay).

9. Test for power on all legs and contactor operation.

Replace unit if faulty.

10. Ensure correct size for machine load; replace weak

breaker.

11. Replace faulty ON button or ON/OFF switch.

12. Check for broken wires or disconnected/corroded

connections, and repair/replace as necessary.

13. Test/repair/replace.

14. Turn switch to FWD/REV; replace bad switch.

15. Test, replace if needed.

Loud, repetitious

noise

coming

from

machine

at or near the

motor.

1. Pulley setscrews or keys are missing or

loose.

2. Motor fan is hitting the cover.

1. Inspect keys and setscrews. Replace or tighten if

necessary.

2. Tighten fan or shim cover, or replace items.

Motor overheats.

1. Motor overloaded.

2. Air circulation through the motor restricted.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

Motor is loud

when cutting.

Overheats or

bogs down in the

cut.

1. Excessive depth of cut or feed rate.

2. RPM or feed rate wrong for cutting operation.

3. Cutting tool is dull.

4. Gear setup is too tight, causing them to bind.

1. Decrease depth of cut or feed rate.

2. Refer to RPM feed rate chart for appropriate rates.

3. Sharpen or replace the cutting tool.

4. Readjust the gear setup with a small amount of

backlash so the gears move freely and smoothly

when the chuck is rotated by hand.

���

Summary of Contents for G0600

Page 3: ... ...

Page 8: ...G0600 20 x 60 Big Bore Lathe 5 ...

Page 9: ... 6 G0600 20 x 60 Big Bore Lathe ...

Page 12: ...G0600 20 x 60 Big Bore Lathe 9 SECTION 1 SAFETY ...

Page 13: ... 10 G0600 20 x 60 Big Bore Lathe ...

Page 19: ... 16 G0600 20 x 60 Big Bore Lathe Hardware Recognition Chart ...

Page 72: ...G0600 20 x 60 Big Bore Lathe 69 Headstock Face and Shift System 0000 Series Parts ...

Page 73: ... 70 G0600 20 x 60 Big Bore Lathe Headstock Shift System 0000 Series Parts ...

Page 74: ...G0600 20 x 60 Big Bore Lathe 71 Headstock Oil Pump System 0000 Series Parts ...

Page 78: ...G0600 20 x 60 Big Bore Lathe 75 Quick Change Gearbox Gear System 1000 Series Series Parts ...

Page 79: ... 76 G0600 20 x 60 Big Bore Lathe Quick Change Gearbox Face 1000 Series Parts ...

Page 80: ...G0600 20 x 60 Big Bore Lathe 77 Quick Change Gearbox Shift System 1000 Series Parts ...

Page 81: ... 78 G0600 20 x 60 Big Bore Lathe Quick Change Gearbox Shift System 1000 Series Parts ...

Page 84: ...G0600 20 x 60 Big Bore Lathe 81 Carriage 2000 Series Parts ...

Page 85: ... 82 G0600 20 x 60 Big Bore Lathe Cross Slide and Carriage 2000 Series Parts ...

Page 86: ...G0600 20 x 60 Big Bore Lathe 83 Compound Rest and Tool Post 2000 Series Parts ...

Page 87: ... 84 G0600 20 x 60 Big Bore Lathe Carriage Oil Pump System 2000 Series Parts ...

Page 90: ...G0600 20 x 60 Big Bore Lathe 87 Apron Face Thread Dial Auto Stop System 3000 Series Parts ...

Page 91: ... 88 G0600 20 x 60 Big Bore Lathe Apron Gearing Halfnut Feed System 3000 Series Parts ...

Page 92: ...G0600 20 x 60 Big Bore Lathe 89 Apron Feed Rod Clutch and Lever System 3000 Series Parts ...

Page 95: ... 92 G0600 20 x 60 Big Bore Lathe Tailstock 4000 Series Parts ...

Page 97: ... 94 G0600 20 x 60 Big Bore Lathe Bed Assembly 5000 Series Parts ...

Page 98: ...G0600 20 x 60 Big Bore Lathe 95 Brake Pedal and Headstock Panels 5000 Series Parts ...

Page 99: ... 96 G0600 20 x 60 Big Bore Lathe Brake System and Change Gears 5000 Series Parts ...

Page 100: ...G0600 20 x 60 Big Bore Lathe 97 Motor and Headstock Mounting 5000 Series Parts ...

Page 101: ... 98 G0600 20 x 60 Big Bore Lathe End Covers and Splash Guard 5000 Series Parts ...

Page 102: ...G0600 20 x 60 Big Bore Lathe 99 Change Gear System 5000 Series Parts ...

Page 105: ... 102 G0600 20 x 60 Big Bore Lathe Steady and Follow Rests 6000 Series Parts ...

Page 110: ... ...

Page 111: ... ...

Page 112: ......

Page 113: ... ...