-20-

G0641 Double Miter Saw

Lowering Speeds

The lowering speeds of the hold-downs and

blades are independently adjustable. The goal is

to synchronize these rates so that the hold-downs

grip the workpiece before the blades begin the

cut. After the cut is complete and the blades are

fully raised, the hold-downs will raise and release

the workpiece.

When making adjustments, first adjust the lower-

ing speed of the blades, then adjust the lowering

speed of the hold-downs.

To adjust the lowering and raising rate of the

saw blades:

1.

DISCONNECT SAW FROM POWER!

adjusting lowering speeds

3.

Secure a scrap piece of the same material

you will use for the production run under the

hold-downs, then lower and secure the front

guard.

4.

Connect the saw to power, turn the motor on,

and use the foot pedal actuator to make test

cuts.

5.

Adjust the lowering and raising speeds of the

blades to produce cuts that are without tear

out (too fast) and without burning (too slow).

Note:

Turning the speed knob in (clockwise)

decreases the speed, and turning out (coun-

terclockwise) increases it.

6.

Continue to make adjustments and test cuts

until you are satisfied with the lowering and

raising speeds of the blade, then re-tighten

the jam nut to secure the setting.

To adjust the lowering rate of the hold-

downs:

1.

DISCONNECT SAW FROM POWER!

2.

Remove the two thumb screws from the front

guard and raise it to the upper position.

When properly adjusted, the hold-downs

prevent the workpiece from being drawn into

the blades or thrown from the saw when cut-

ting. Always make sure the hold-downs are

properly adjusted for the workpiece and that

they securely clamp the workpiece before

the blades begin the cut.

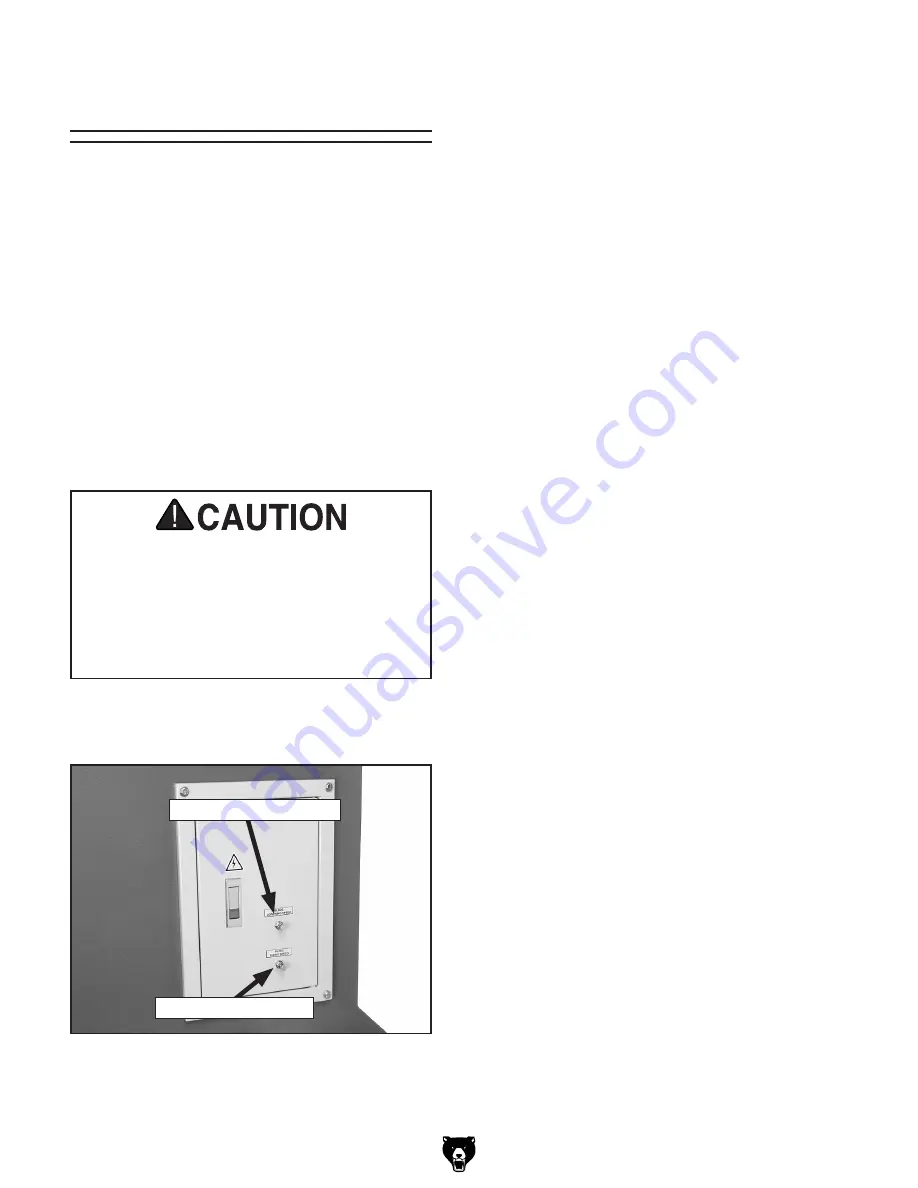

Figure 17.

Saw blade lowering and raising

speed controls (on right side of machine).

Raising Speed Knob

Lowering Speed Knob

2.

Loosen the jam nuts on the blade lowering

and raising speed knobs (see

Figure 17

).

Summary of Contents for G0641

Page 2: ......

Page 5: ...G0641 Double Miter Saw 3 Machine Data Sheet machine data sheet...

Page 7: ...G0641 Double Miter Saw 5 Safety Instructions for Machinery...

Page 8: ...6 G0641 Double Miter Saw...

Page 41: ...G0641 Double Miter Saw 39 SECTION 8 PARTS Cabinet Breakdown...

Page 43: ...G0641 Double Miter Saw 41 Drive System Breakdown table inserts...

Page 47: ...G0641 Double Miter Saw 45 Electrical Lubrication Systems Breakdown...

Page 49: ...G0641 Double Miter Saw 47 Pneumatic System Breakdown pneumatic system breakdown...

Page 52: ...50 G0641 Double Miter Saw...

Page 53: ......

Page 54: ......

Page 55: ...WARRANTY AND RETURNS WARRANTY AND RETURNS...

Page 56: ......