-34-

Model G0654 (Mfg. Since 9/07)

SEcTION 6: MAINTENANcE

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily check:

•

vacuum all dust on and around the

machine.

•

Wipe down tables and all other unpainted

cast iron with a metal protectant.

•

Worn or damaged wires.

•

any other unsafe condition.

Monthly check:

•

v-belt tension, damage, or wear.

•

Clean/vacuum dust buildup from inside cabi-

net and off motor.

Schedule

since all bearings are sealed and permanently

lubricated, simply leave them alone until they

need to be replaced. do not lubricate them.

the following components require periodic lubri-

cation. Be careful not to over-lubricate them.

large amounts of lubricant will attract sawdust,

causing the metal components to gum up and

bind.

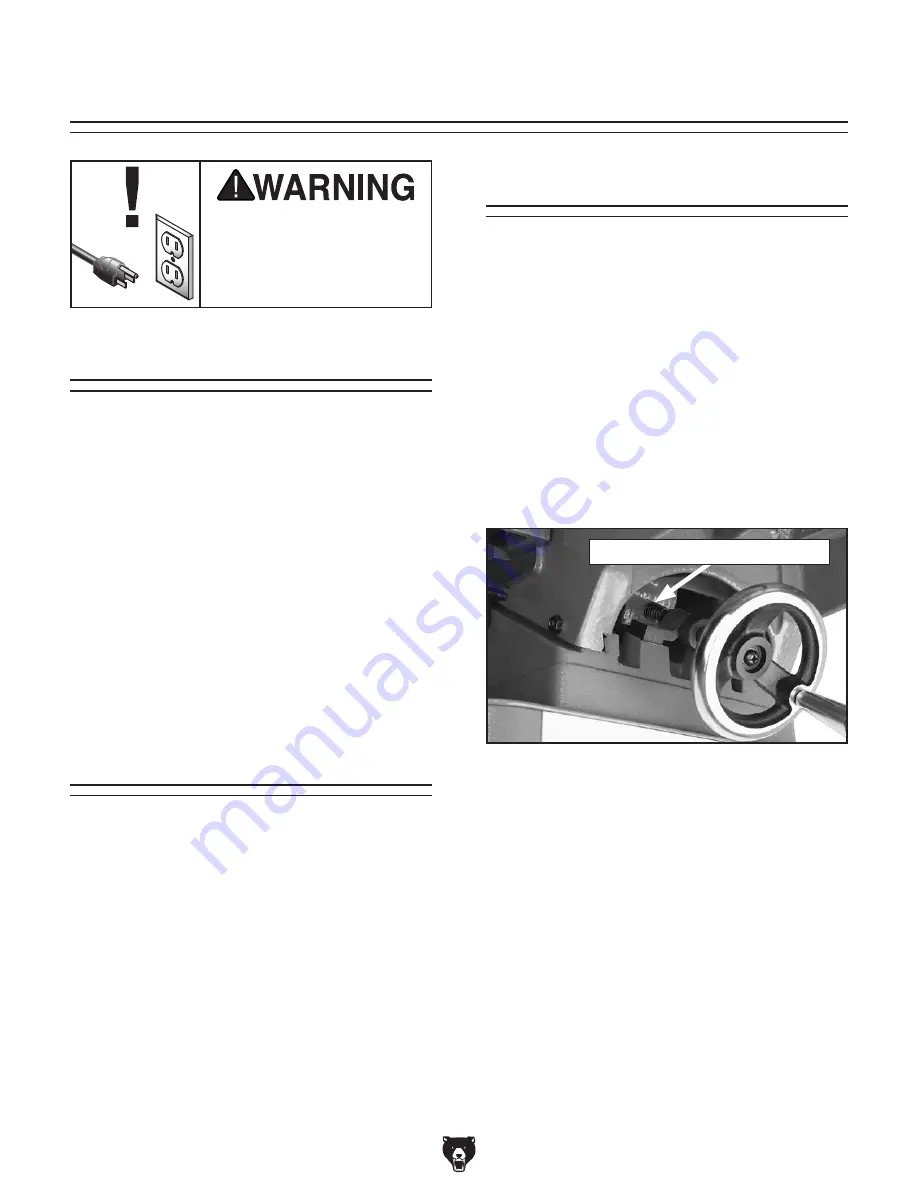

figure 60. leadscrew lubrication location.

Leadscrew: lubricate the outfeed table leadscrew

with light machine oil as needed. see the location

shown in

figure 60 and part 41 on page 46. Wipe

off excess oil and sawdust with a cloth.

Lubrication

vacuum excess wood chips and sawdust, and

wipe off the remaining dust with a dry cloth—this

ensures moisture from wood dust does not remain

on bare metal surfaces. treat all unpainted cast

iron and steel with a non-staining lubricant after

cleaning. We recommend products like slipit

®

,

g96

®

gun treatment, or Boeshield

®

t-9 (see

page 32 for more details).

cleaning

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

leadscrew lubrication location

Summary of Contents for G0654

Page 56: ......