TAPE ALONG EDGES--PLEASE DO NOT STAPLE

FOLD ALONG DOTTED LINE

FOLD ALONG DOTTED LINE

GRIZZLY INDUSTRIAL, INC.

P.O. BOX 2069

BELLINGHAM, WA 98227-2069

Place

Stamp

Here

Name_______________________________

Street_______________________________

City______________State______Zip______

Send a Grizzly Catalog to a friend:

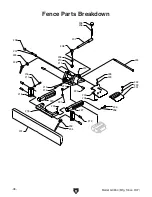

Summary of Contents for G0654

Page 56: ......