-44-

Model G0690/G0691 (Mfd. 6/15+)

A ripping blade (described on

Page 34) is typically

the best blade to use for cutting dadoes when

using a standard blade, because it removes saw-

dust very efficiently.

To use a standard saw blade to cut dadoes:

1. DISCONNECT SAW FROM POWER!

2. Mark the width of the dado cut on the

workpiece.

Include marks on the edge of the

workpiece so the cut path can be aligned

when the workpiece is lying on the table.

Cutting Dadoes with a Standard

Blade

6. Reconnect the saw to the power source and

turn the saw

ON. Allow the blade to reach full

speed, then perform the cutting operation.

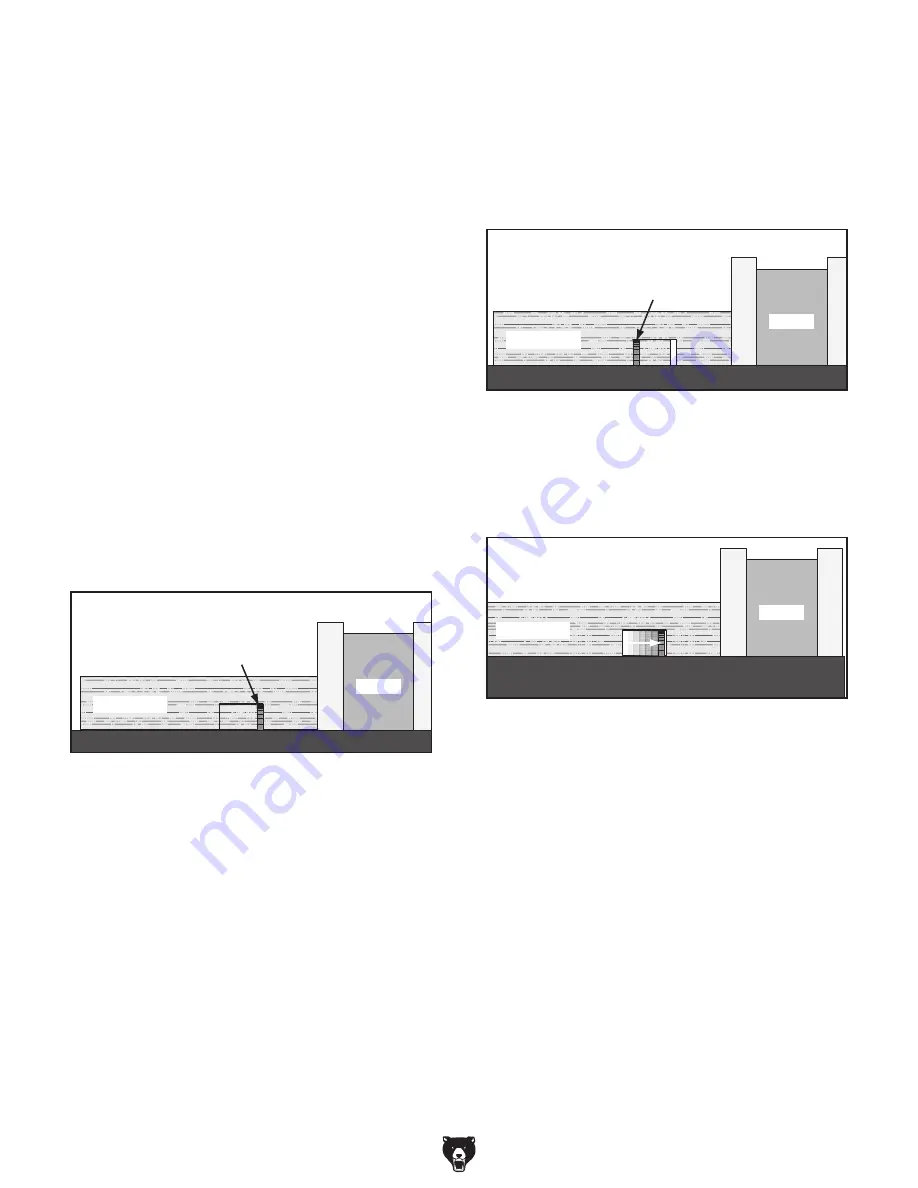

7. Repeat the cutting operation on the other

side of the dado channel, as shown in

Figure

61.

8. Make additional cuts (see Figure 62) in the

center of the dado to clear out the necessary

material. The dado is complete when the

channel is completely cleared out.

Workpiece

Fence

Cut 2

Blade

Figure 61. Second cut for a single blade dado.

Workpiece

Fence

Cuts 3+

Figure 62. Additional single blade dado cuts.

Blade

Workpiece

Fence

Cut 1

Figure 60. First cut for a single-blade dado.

3. Raise the blade up to the desired depth of cut

(depth of dado channel desired).

4. Set the saw up for the type of cut you need

to make, depending on if it is a rip cut (

Page

40) or crosscut (Page 41).

5. Align the blade to cut one of the dado sides,

as shown in

Figure 60.

Summary of Contents for G0690

Page 20: ...18 Model G0690 G0691 Mfd 6 15 Hardware Recognition Chart...

Page 92: ......