Model G0699 (Mfd. Since 5/15)

-25-

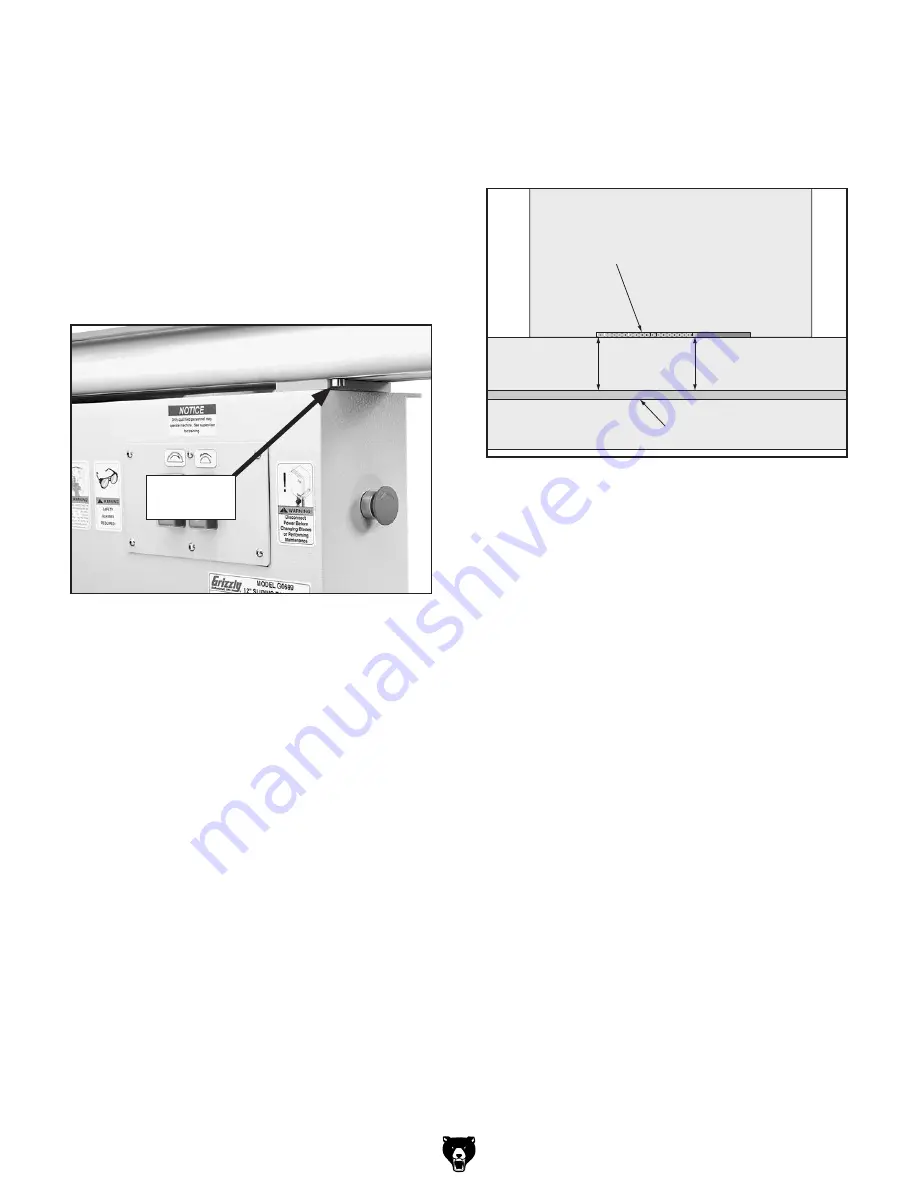

12. Have two people turn the sliding table assem-

bly right side up, then have another person

guide the T-bolts into the mounting holes as

the sliding table is lowered onto the frame.

Important: As you align the sliding table

parallel with the main saw blade in the next

steps, the locating cap screw shown in

Figure 21 must remain against the right side

of the frame before securing the sliding table

in place. This will correctly position the sliding

table with the rest of the machine.

Figure 21. Sliding table locating cap screw

against the right side of the frame.

Locating

Cap Screw

In the next steps, you will align the sliding

table parallel with the table saw. This is nec-

essary to ensure straight cutting operations

and to prevent workpieces from binding and

kicking back.

13. Move the sliding table all the way back.

14. Tilt the main saw blade to 0° and raise it all

the way up.

15. Use the felt tip pen to mark the right blade

edge that is even with the table.

A

B

Main Saw Blade

Sliding Table T-Slot

Figure 22. Measuring the distance between

sliding table T-slot and main blade.

17. Move the sliding table all the way forward,

rotate the saw blade so the mark you made

in

Step 15 is at location "B", then take the

measurement of "B".

— If the difference is equal to or less than

0.004" between the "A" and "B" mea-

surements, the sliding table parallelism is

acceptable. Continue with

Step 21.

— If the difference between the "A" and "B"

measurements is greater than 0.004", the

sliding table parallel adjustment bolts need

to be re-adjusted. Continue with the next

step.

16. Use the adjustable square and feeler gauges

to measure the distance between the sliding

table T-slot and the main saw blade at the

mark you made in

Step 15. This is distance

"A" shown in

Figure 22.

Summary of Contents for G0699

Page 21: ...Model G0699 Mfd Since 5 15 19 5mm Hardware Recognition Chart...

Page 108: ......