Model G0699 (Mfd. Since 5/15)

-27-

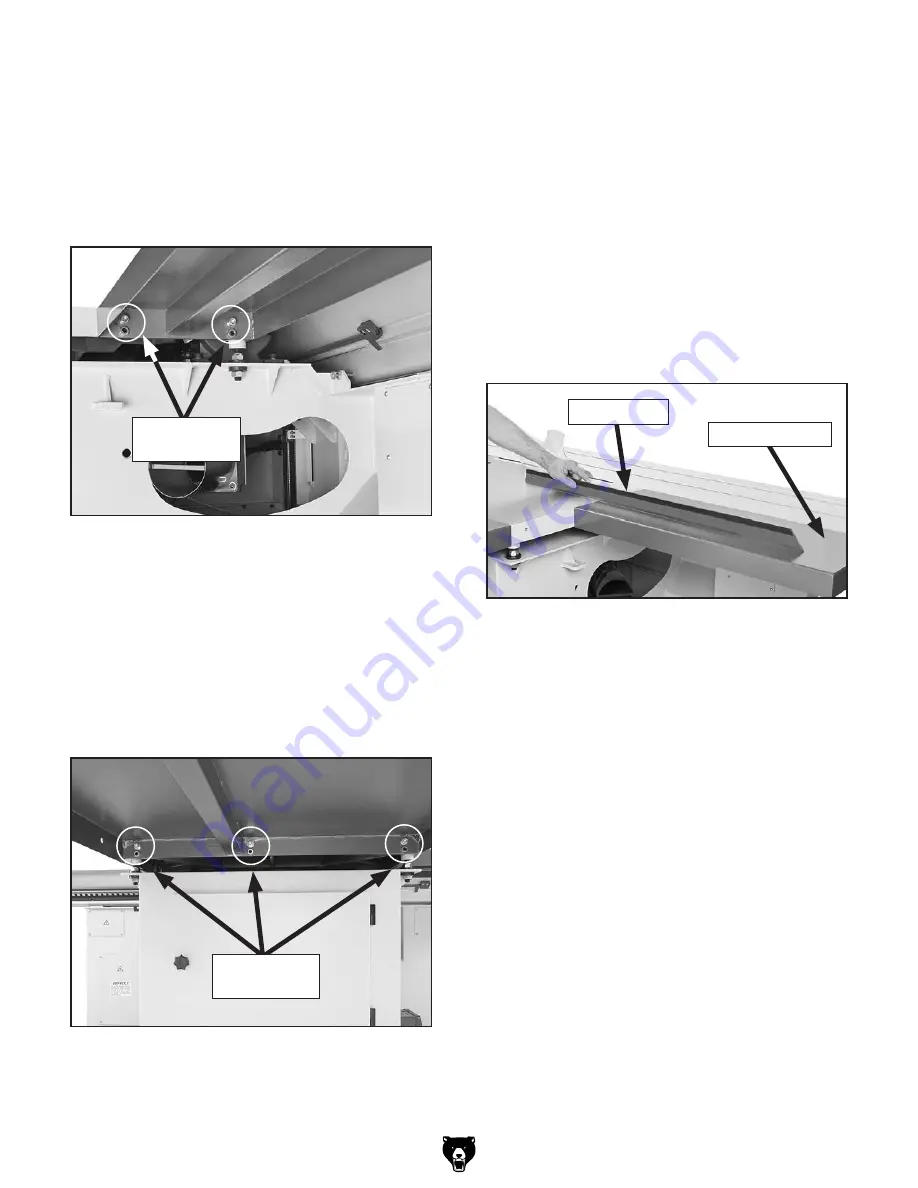

25. With the help of another person to hold the

forward extension wing, attach it to the cast

iron table with (2) M10-1.5 x 25 cap screws,

10mm lock washers, and 10mm flat washers,

as shown in

Figure 27.

Hand tighten the cap screws for now—they

will be fully tightened in a later step.

Figure 27. Forward extension wing attached (as

viewed under the wing).

Cap Screws

& Set Screws

26. With the help of two other people to hold

the rear extension wing, attach it to the cast

iron table with (3) M10-1.5 x 25 cap screws,

10mm lock washers, and 10mm flat washers,

as shown in

Figure 28.

Hand tighten the cap screws for now—they

will be fully tightened in a later step.

27. Thread (5) M10-1.5 x 20 set screws into

the threaded holes under each of the

extension wing cap screws on both wings

(see

Figures 27–28).

Make sure the set screws do not stick out

from the wing mating surface, which would

interfere with the leveling process in the next

step.

28. Place the straightedge across the cast iron

table and an extension wing, then adjust the

set screws in or out to make the top surface

of the wings even with that of the cast iron

table (see

Figure 29).

Figure 28. Rear extension wing attached.

Cap Screws

& Set Screws

29. When the top surfaces are even, thread (5)

M10-1.5 hex nuts onto the set screws without

changing their settings. Fully tighten the hex

nuts to secure the set screws in place.

30. Fully tighten the extension wing cap screws,

then re-check to make sure the top surfaces

remain even.

— If the top surfaces did not remain even after

tightening the cap screws, loosen them,

then repeat

Steps 28–30 until they remain

even.

Figure 29. Using a straightedge to make sure

the table/wing top surfaces are even.

Extension Wing

Straightedge

Summary of Contents for G0699

Page 21: ...Model G0699 Mfd Since 5 15 19 5mm Hardware Recognition Chart...

Page 108: ......