Model G0699 (Mfd. Since 5/15)

-57-

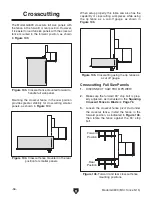

4. Use a precision ruler against a tooth of the

blade, then adjust the fence so that the 2"

mark on the fence scale is exactly 2" from the

blade tooth, as shown in

Figure 107.

5. Carefully lift the crosscut fence up, fully tight-

en the pivot stud, then re-insert the stud into

the hole. Re-check the spacing between the

end block and blade—if necessary, loosen

the stud and repeat

Steps 3–5 until the spac-

ing is correct.

6. Set either crosscut fence flip stop to the

desired width-of-cut.

Note: Extend the crosscut fence slide if the

workpiece is more than 74".

7. Load the workpiece onto the table saw. The

set up should look similar to

Figure 103 on

the previous page.

8. Once all the necessary safety precautions

have been taken, then perform the cutting

operation.

Crosscutting Smaller Panels

Follow the same steps in the

Crosscutting Full

Size Panels subsection on Page 56, but mount

the crosscut fence in the rear position, as indi-

cated in

Figure 106 on the previous page. Then,

load the workpiece so your setup looks similar to

Figure 104 on the previous page.

Crosscutting Using Rip Fence as a

Cut-Off Gauge

1. Follow the same steps in the Crosscutting

Full Size Panels subsection on Page 56, but

mount the crosscut fence in the rear position,

as indicated in

Figure 106 on the previous

page.

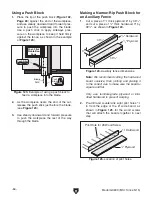

2. Position the rip fence for the desired width-of-

cut, then slide the leading end of the rip fence

behind the front edge of the main blade, as

shown in

Figure 108.

3. Take all the necessary safety precautions,

connect the saw to power, then perform the

cutting operation.

Figure 107. Setting the correct space between

the crosscut fence and blade for rip cutting.

End

Block

2" Mark

Figure 108. Proper rip fence position when using

it as a cut-off gauge.

Front Edge

of Blade

Rip Fence

Leading Edge

Rip Fence

When using the rip fence with the crosscut

fence, the rip fence must be positioned

behind the front edge of the blade to pre-

vent the workpiece from binding and caus-

ing a kickback hazard.

Summary of Contents for G0699

Page 21: ...Model G0699 Mfd Since 5 15 19 5mm Hardware Recognition Chart...

Page 108: ......