Model G0699 (Mfd. Since 5/15)

-69-

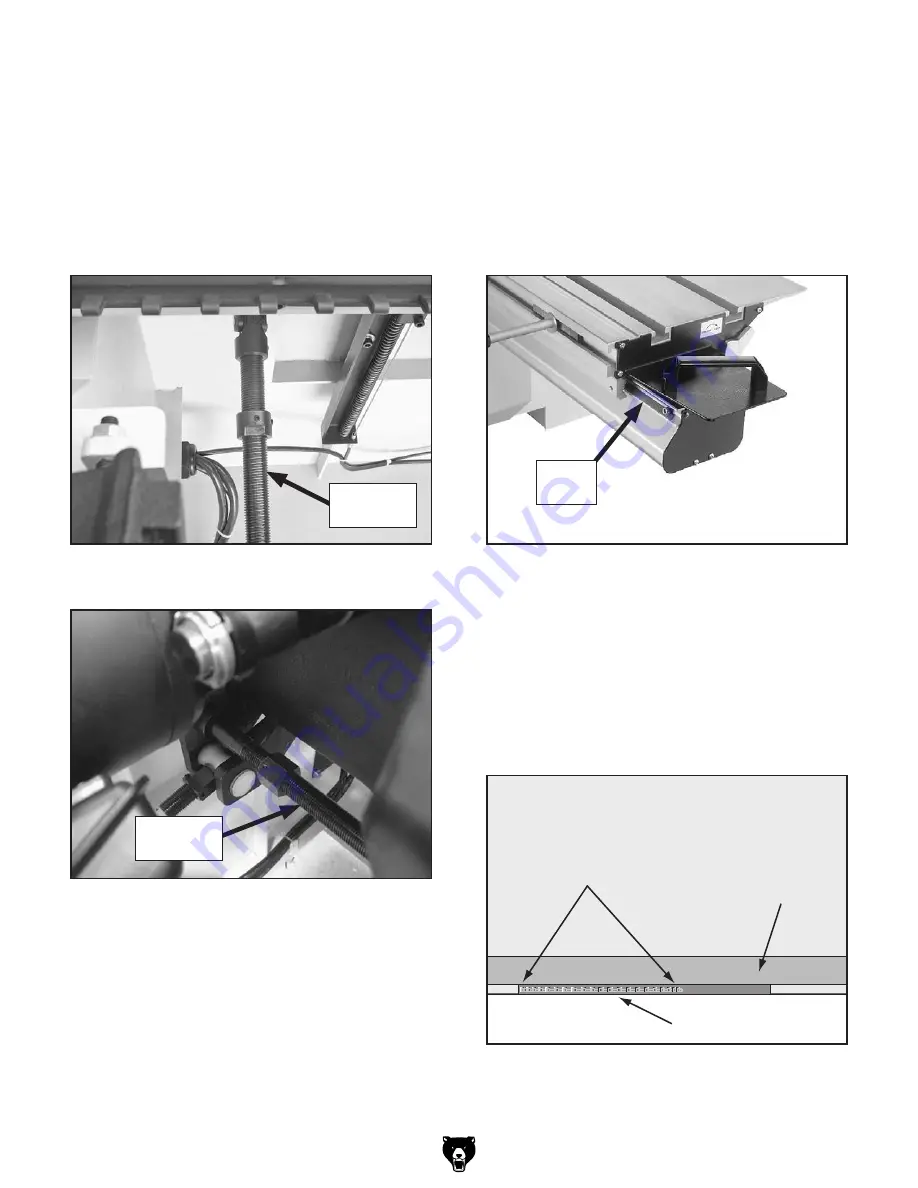

Leadscrews

Use mineral spirits and shop rages to clean away

grime and debris from the full lengths of the tilt

and elevation leadscrews (see

Figures 134–135).

Then, apply a thin coat of light machine oil (see

Accessories on Page 59) to their full lengths with

a shop rag. Move the leadscrews through their

full range of movement several times to evenly

distribute the oil.

Sliding Table Ways

There are steel ways (see

Figure 136) on both

sides of the sliding table that fit between the top

and the base and allow these parts to slide past

each other. Clean the ways with mineral spirits

and shop rags, then apply a thin coat of light

machine oil with a shop rag. Move the sliding

table through its full range of movement several

times to evenly distribute the oil.

Replacing Main Table

Replace the main table in the reverse steps from

which it was removed.

Before re-tightening the mounting hex nuts, use

a straightedge to adjust the table position so that

the leading edge of the blade gap is parallel to

saw blade, as illustrated in

Figure 137.

Straightedge

Measuring

Locations

Main Table

Main Blade

Figure 137. Measuring locations for squaring the

main table to the blade.

Figure 136. Sliding table way (1 of 2).

Way

(1 of 2)

Figure 134. Tilt leadscrew (viewed through the

gap between the sliding table and cabinet).

Tilt

Leadscrew

Figure 135. Elevation leadscrew

(viewed from between the motors).

Elevation

Leadscrew

Summary of Contents for G0699

Page 21: ...Model G0699 Mfd Since 5 15 19 5mm Hardware Recognition Chart...

Page 108: ......