Model G0699 (Mfd. Since 5/15)

-75-

6. Move the sliding table all the way forward,

rotate the saw blade so the mark you made in

Step 4 is at location "B", then take the mea-

surement of "B".

— If the difference is equal to or less than

0.004" between the "A" and "B" measure-

ments, the sliding table parallelism to the

saw blade is acceptable and adjustment is

necessary.

— If the difference between the "A" and "B"

measurements is greater than 0.004", the

sliding table parallel adjustment bolts need

to be re-adjusted. Continue with the next

step.

7. Loosen the three sliding table mounting hex

nuts that hold the sliding table in place.

Note: Access two of the hex nuts by remov-

ing the access panels on both sides of the

frame, and the middle hex nut through the 5"

dust port gap in the cabinet side.

9. Make sure the sliding table is up against the

adjustment bolts, then repeat

Steps 5, 6 and

8 until the difference between the "A" and "B"

measurements is acceptable.

10. Re-tighten the jam nuts on the adjustment

bolts.

11. Make sure the sliding table is against both

adjustment bolts, then re-tighten the mount-

ing hex nuts to secure the table in place.

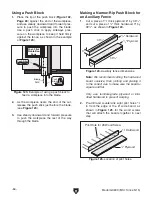

Figure 144. Sliding table parallel adjustment bolt

(1 of 2).

Parallel Adjustment

Bolt & Jam Nut (1 of 2)

8. Loosen the jam nuts on the sliding table par-

allel adjustment bolts (see

Figure 144) that

are on both sides of the frame behind the

sliding table, then adjust the bolts in or out in

small increments to change the parallel rela-

tionship of the sliding table to the saw blade.

Summary of Contents for G0699

Page 21: ...Model G0699 Mfd Since 5 15 19 5mm Hardware Recognition Chart...

Page 108: ......