Model G0701 (Mfd. Since 9/17)

-61-

9. Gently tap the lower part of the guide post in

the appropriate direction until there is no gap

between the square and the guide post.

10. Tighten the screws shown in Figure 75, and

verify that the guide post stays parallel with

the blade along its full path of movement. If

necessary, repeat

Steps 8–10 until it is.

Checking/Adjusting Guide Post

Parallel with Blade Front-to-Back

1. DISCONNECT MACHINE FROM POWER!

2. Remove the blade.

3. Place one hand under the upper blade guide

assembly to keep it from falling, loosen the

two cap screws that secure the guide assem-

bly to the guide post (see

Figure 76), then

remove the guide assembly.

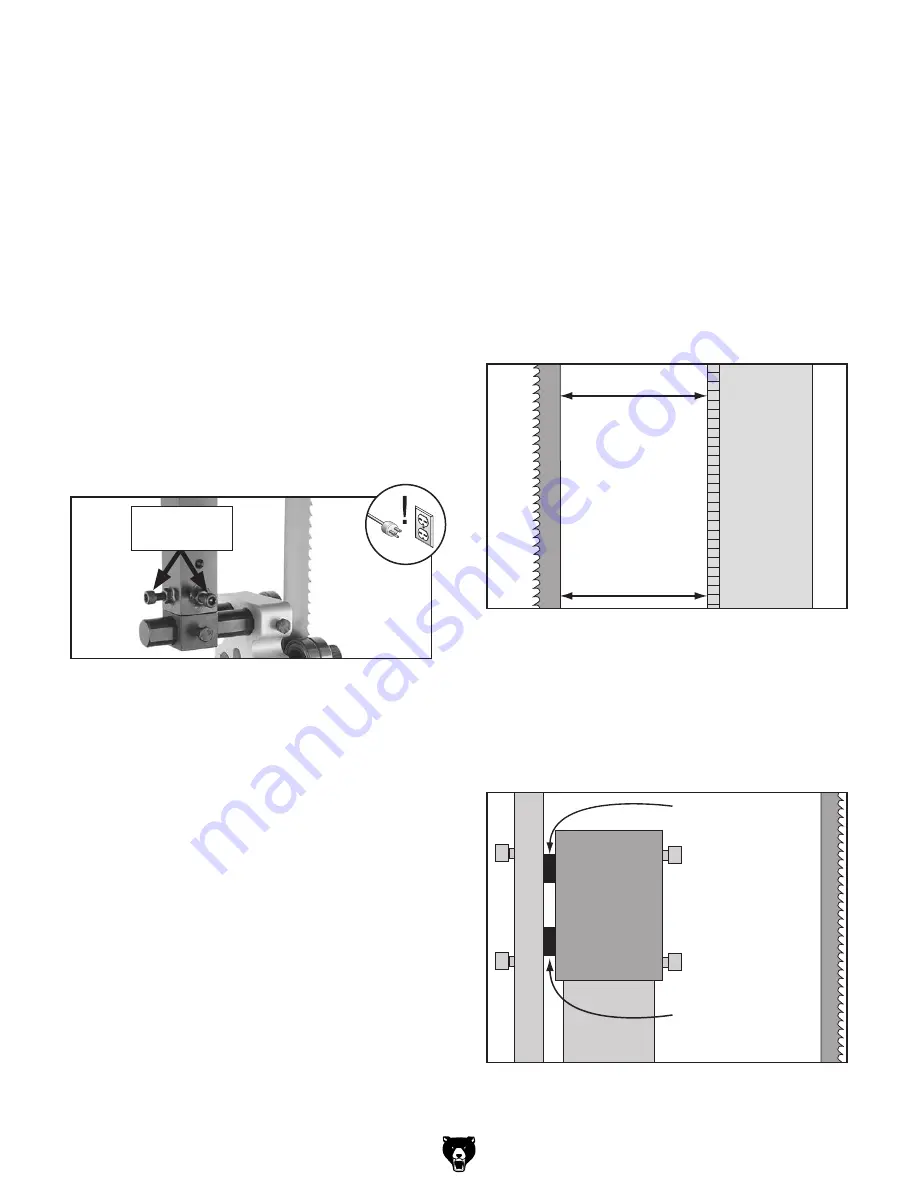

Distance "A"

Distance "B"

(Right Side View)

Guide Post

Blade

Figure 77. Example of measuring distance

between rack and blade at top of guide post.

9. Loosen the four screws shown in Figure 75

enough to fit metal shims (wide enough to fit

the full width of the guide bracket), between

the frame and the guide post bracket (see

Figure 78).

Shim "B"

(Left Side View)

Shim "A"

Frame

Blade

Guide

Post

Guide

Bracket

Figure 78. Location for placing shims. (Shim

thickness not drawn to scale.)

Figure 76. Guide block cap screws (blade guard

removed for photo clarity).

Guide Block

Cap Screws

4. Remove the two cap screws and hex bolt that

secure the upper blade guard to the guide

post, then remove the blade guard.

5. Re-install the blade and re-tension it.

6. Loosen the guide post lock knob, lower the

guide post to within 1" of the table top, then

tighten the lock knob.

7. Measure the distance "A" between the top

front face of the guide post rack and the back

of the blade (see

Figure 77).

8. Measure the distance "B" between the bot-

tom front face of the guide post rack and the

back of the blade (see

Figure 77).

—If the measurements taken in

Steps 7–8

are equal, no adjustments need to be

made. Go to

Step 11.

—If the measurements taken in

Steps 7–8

are not equal, go to

Step 9.