-18-

Model G0726 (Mfg. Since 7/11)

Lifting & Placing Mill

Lifting and placing the mill requires at least two

other people for assistance and a forklift with two

lifting straps, lifting chain, and a safety hook rated

for at least 4500 lbs. each.

To lift and move the mill:

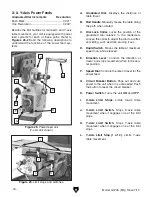

1. Position ram and headstock as illustrated in

Figure 5 (refer to Head Movement on Page

32 and Ram Movement on Page 33 for

detailed instructions).

Note: After re-positioning ram and head-

stock, make sure they are locked in place to

prevent unexpected movement during lifting

and moving.

2. Place lifting straps under ram and connect

them to forklift safety hook and chain, as illus-

trated in

Figure 6.

Note: Place padding between straps and mill

to protect ram and ways, and to keep from

cutting lifting straps.

3. Unbolt mill from shipping pallet.

4. With your assistants steadying the mill to

keep it from swaying, lift mill a couple of

inches.

— If mill tips to one side, lower it to the ground

and adjust ram or table to balance load.

Make sure to re-tighten lock levers and

bolts before lifting mill again.

— If mill lifts evenly, continue to move it to its

permanent location.

The Model G0726 is a

heavy machine. Serious

personal injury may occur

if safe moving methods are

not used. To be safe, get

assistance and use power

equipment rated for at least

4500 lbs. to move the ship-

ping crate and remove the

machine from the crate.

Figure 5. Correct ram and head position before

lifting.

Figure 6. Lifting straps attached to safety hook

and chain in preparation for lifting.

Safety Hook

& Chain

Lifting

Straps