-24-

Model G0726 (Mfg. Since 7/11)

15. WITHOUT resetting EMERGENCY STOP

button, turn SPINDLE SWITCH to the for-

ward (FOR) position and press START but-

ton—machine should not start.

—If the machine does start (with EMERGENCY

STOP button pushed in), turn MASTER

POWER SWITCH

OFF, then immedi-

ately disconnect power to machine. The

EMERGENCY STOP button safety feature

is not working correctly. This safety feature

must work properly before proceeding with

regular operations. Call Tech Support for

help.

16. Reset EMERGENCY STOP button, then

press START button to start spindle rotation

again.

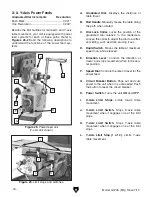

17. Point coolant nozzle onto table, turn

COOLANT SWITCH to "

l" or ON, then open

nozzle valve and check for proper operation

of coolant system.

18. Turn coolant pump OFF, then turn SPINDLE

SWITCH to STOP position to halt spindle

rotation.

10. Verify that machine is operating correctly.

—When operating correctly, machine runs

smoothly with little or no vibration or rub-

bing noises.

— Investigate and correct strange or unusu-

al noises or vibrations before operating

machine further. Always stop machine and

disconnect it from power before investigat-

ing or correcting potential problems.

11. Rotate SPINDLE SWITCH to the STOP posi-

tion and wait for spindle to completely stop.

12. Pull Z-axis crank away from limit switch to be

able to properly perform the next step.

13. Verify power is not connected out of phase

by using Z-axis UP and DOWN buttons on

control panel to raise and lower knee.

—If knee moves opposite of button used, stop

machine, disconnect machine from power,

then swap any two of the three incoming

power wires that connect to electrical box

terminal bar (refer to

Power Connection

on

Page 22 for detailed information).

14. Press EMERGENCY STOP button to turn

machine

OFF, then wait for spindle to stop on

its own.