-36-

Model G0726 (Mfg. Since 7/11)

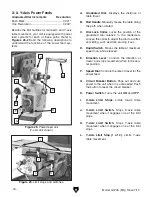

Spindle Downfeed

Spindle downfeed movement on the mill is con-

trolled by three mechanisms: 1) The coarse

downfeed lever for rapid spindle movement, 2)

the fine downfeed handwheel for slower spindle

movement, and 3) the auto-downfeed system for

powered spindle movement.

Downfeed Controls

Use

Figure 41 and the following descriptions to

become familiar with the spindle downfeed con-

trols.

A. Auto-Downfeed Rate Selector. Selects one

of the three auto-downfeed rates.

B. Fine Downfeed Handwheel. Manually con-

trols slow spindle downfeed.

C. Auto-Downfeed Direction Pin. Starts, stops,

and reverses the auto-downfeed direction.

D. Fine Downfeed Clutch Lever. Engages the

fine/auto-downfeed gears.

E. Downfeed Scale. Used with the quill dog,

shows the depth of spindle downfeed in

inches.

F. Quill Lock Lever. Secures the quill in place

for increased stability during operations.

G. Downfeed Stop & Locking Wheel. Sets

the depth of spindle downfeed. The stop is

threaded into position, then the locking wheel

is used to secure it in place.

H. Coarse Downfeed Lever. Manually controls

quick spindle downfeed.

I. Quill Dog. Moves with the quill and spin-

dle, and disengages the downfeed clutch

lever when it contacts either the top or the

downfeed stop.

J. Downfeed Selector. Sets the mill for manual

downfeed or auto-downfeed control.

When spindle rotation is reversed, either

by changing the spindle speed range or by

using the spindle direction switch, the direc-

tion of spindle auto-downfeed will reverse.

Figure 41. Downfeed controls.

A

I

J

H

G

F

E

D

C

B