-22-

Model G0745 (Mfg. Since 11/13)

Reversing Jaws

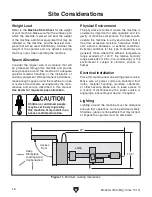

the included 3-jaw scroll chuck features revers-

ible hardened steel jaws (see

figure 18) that

move in unison to converge evenly against con-

centric workpieces.

figure 18. Chuck with reversible jaws.

Tall Sides

Facing Each Other

Low Side

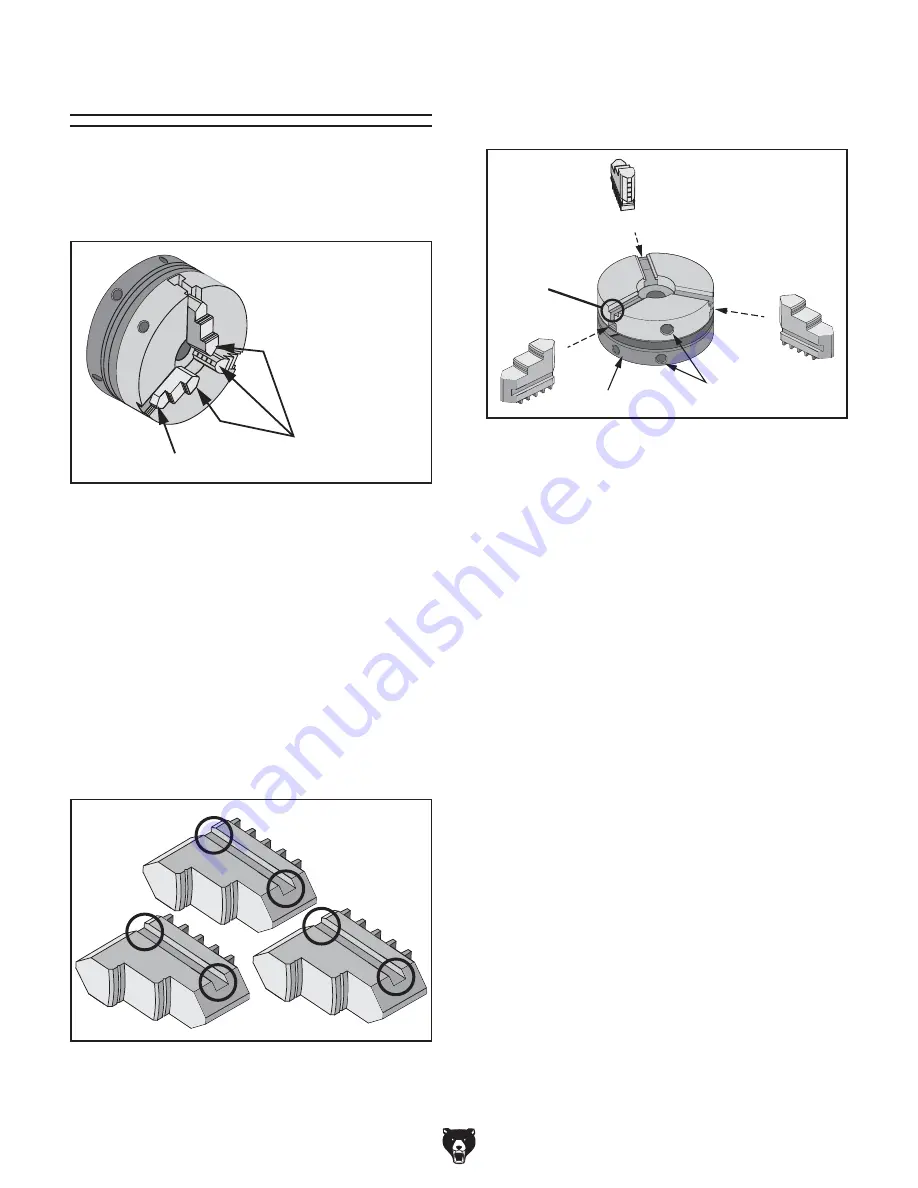

using the stamped numbers, the jaws are installed

in numerical order in the jaw guides (see

figure

20), so they will converge.

figure 20. Jaw installation sequence using

numbers stamped on tall end of jaw.

Jaw Guide

1

2

3

Key Holes

Outer Ring

To reverse the jaws:

1. disCoNNECt lathE FroM poWEr!

2. use an appropriate device to protect the

ways during the installation process (refer

to

Installation & Removal Device on page

20).

3. insert chuck keys into holes in chuck and

outer ring (see

figure 20). hold chuck key

stationary while turning outer ring counter-

clockwise, then back jaws out and remove

them.

4. use mineral spirits to clean debris and grime

from jaws and chuck jaw guides.

When installing the jaws, it is important to make

sure they are installed correctly. incorrect installa-

tion will result in jaws that do not converge evenly

and are unable to securely clamp a workpiece.

all of the tall ends of the jaws—or all of the low

ends—should face each other when installed (see

figure 18). the jaws should be oriented so they

correctly hold the workpiece (refer to

figure 22

on

page 23).

Each end of a jaw is stamped with a number (1, 2,

or 3), as shown in

figure 19.

figure 19. Numbers stamped into each end of

jaws.

3

1

2

2

3

1

Summary of Contents for G0745

Page 44: ... 42 Model G0745 Mfg Since 11 13 Figure 47 Circuit board ...

Page 52: ......