-24-

Model G0746/G0749 (Mfg. Since 3/13)

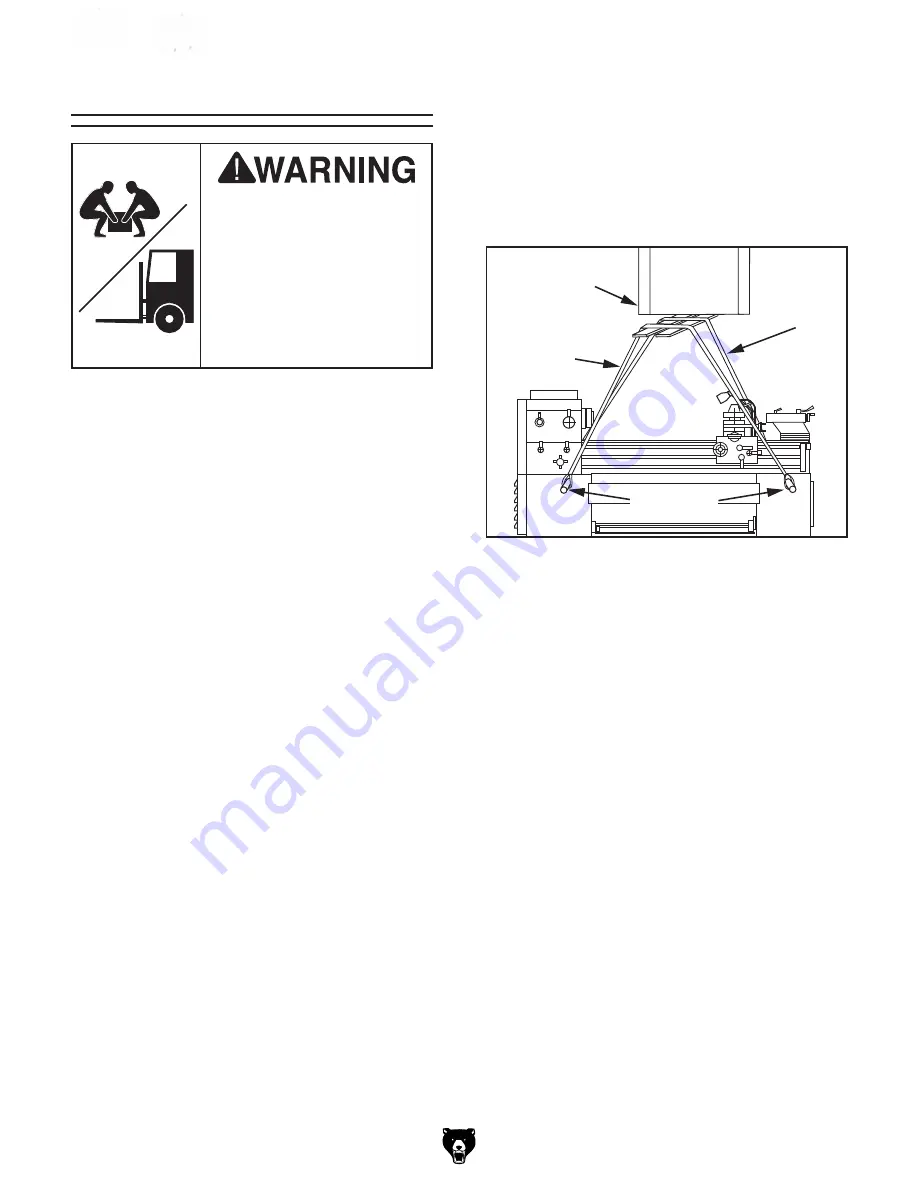

Power Lifting

Equipment

Lifting

Straps

Use Blocks to Space Straps Away

from Control Rod, Feed Rod, Leadscrew &

Prevent Bending During Lifting

Hardwood

Blocking

Hardwood

Blocking

Lifting & placing

do not attempt to lift or move this lathe without

using the proper lifting equipment (such as forklift

or crane) or the necessary assistance from other

people. Each piece of lifting equipment must be

rated for at least 6800 lbs to support dynamic

loads that may be applied while lifting. refer to

Needed for Setup on page 20 for details.

To lift and move the lathe:

1. remove the shipping crate top and sides,

then remove the small components from the

shipping pallet.

2. Move the lathe to its prepared location while

it is still attached to the shipping pallet.

3. Unbolt the lathe from the shipping pallet.

4. to balance the load for lifting, move the

tailstock and carriage to the extreme right

end of the bedway, then lock them in place.

Note:

Before attempting to move the car-

riage, make sure the carriage lock is loose,

the half nut is disengaged, and the power

feed is disengaged (feed selection lever).

5. remove the splash guard so it does not get

damaged when the lathe is raised.

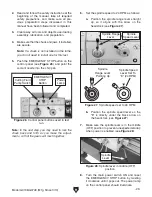

6. insert round steel bar stock through the four

lifting holes (see

figure 16).

Note: To properly support the lathe and

avoid damaging lathe components, bar stock

should be at least 1" diameter thick and 49"

long, so it projects 14" from both sides of the

lathe when installed.

7. attach the lifting straps to the bar stock and

the power lifting equipment (see

figure 16).

Make sure there is enough space between

the straps and the control rod, feed rod,

leadscrew and electrical cabinet to prevent

putting pressure on these components when

lifting.

8. raise the lathe a couple of inches and check

the balance of the load. have two other peo-

ple carefully steady the lathe to help prevent

it from swinging.

— if the load is not safely balanced, immedi-

ately lower the lathe and resolve the issue

before attempting to lift it again.

9. raise the lathe enough to clear the shipping

pallet and carefully remove the pallet.

— if you plan to use the included leveling

bolts and hex nuts to level the lathe, install

them now.

10. lower the lathe into position.

11. re-install the splash guard.

Power Lifting

Equipment

Bar Stock

Rear

Lifting

Strap

Front

Lifting

Strap

figure 16. Example of lathe setup for lifting.

HEAvy LifT!

Straining or crushing injury

may occur from improperly

lifting machine or some of

its parts. To reduce this risk,

get help from other people

and use a fork lift (or other

lifting equipment) rated for

weight of this machine.