Model G0746/G0749 (Mfg. Since 3/13)

-37-

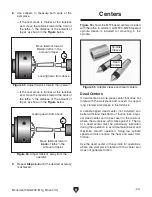

changing Jaw Set

the 3-jaw scroll chuck included with the lathe

features inside and outside hardened steel jaw

sets (see

figure below), which move in unison to

center a concentric workpiece.

When installing the jaws, it is important to make

sure they are installed correctly. incorrect installa-

tion will result in jaws that do not converge evenly

and are unable to securely clamp a workpiece.

figure 39. Chuck and jaw selection.

Inside Set

Outside Set

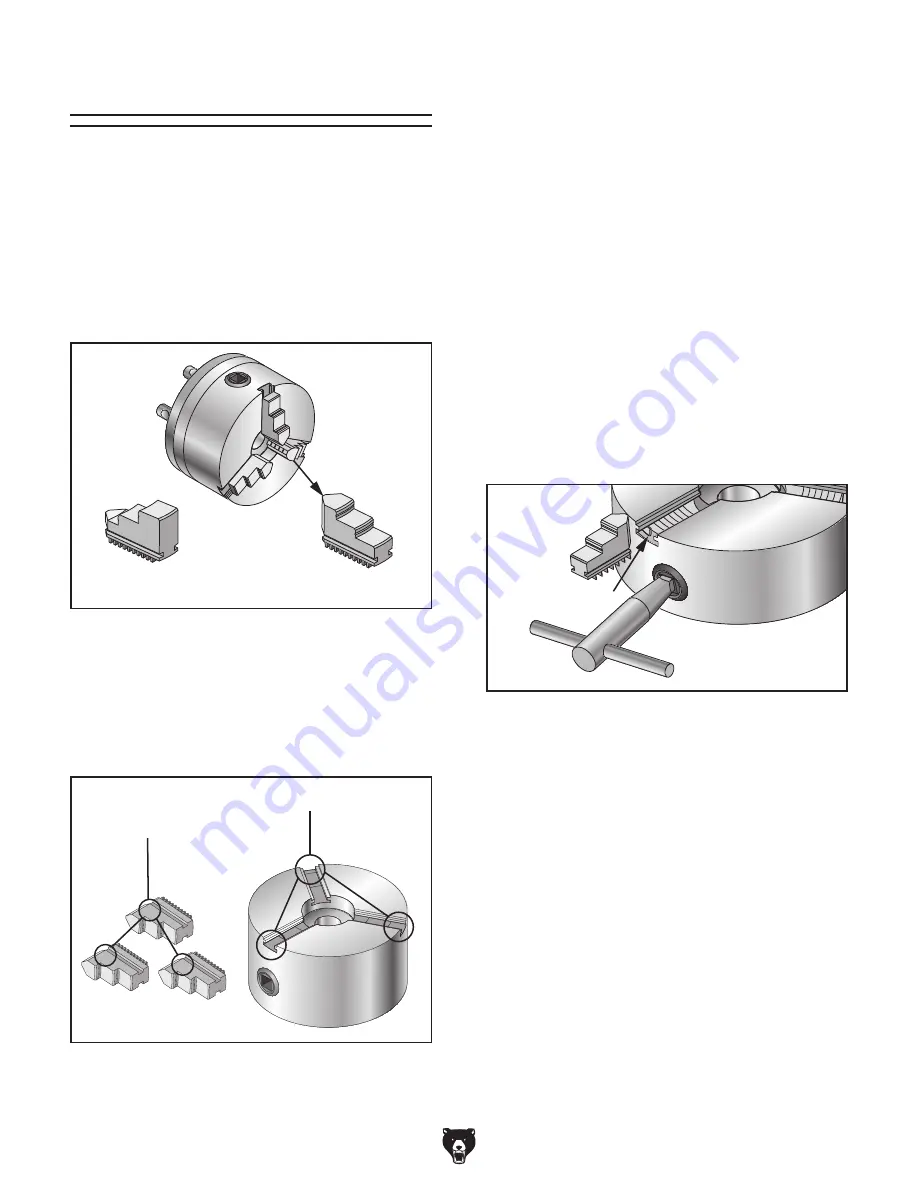

figure 40. Jaw guide and jaw numbers.

Jaw Guides

1

2

3

Jaw Numbers

Jaws are numbered from 1–3 (see

figure below).

the number is typically stamped on the side

or bottom. Jaws are designed to be installed in

numerical order in the jaw guides, so they will hold

a concentric workpiece evenly.

To change the jaw set:

1. disCoNNECt lathE FroM poWEr!

2. place a piece of plywood over the bedways to

protect them from potential damage.

3. insert the chuck key and turn it counterclock-

wise to back the jaws out and remove them.

4. Use mineral spirits to clean the debris and

grime from the jaws and chuck jaw guides.

5. apply a thin coat of white lithium grease to

surfaces of removed jaw set. store in a safe

place free from moisture and abrasives.

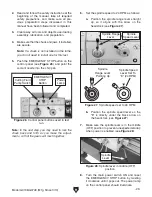

6. rotate chuck key clockwise until you see

the tip of the scroll-gear lead thread begin to

enter a jaw guide (see

figure 38).

Lead Thread

1

figure 41. lead thread on scroll gear.

7. insert jaw #1 into the jaw guide and hold the

jaw against the scroll-gear.

8. rotate the chuck key clockwise one turn to

engage the tip of the scroll-gear lead thread

into the jaw. pull the jaw; it should be locked

into the jaw guide.

9. install the remaining jaws in numerical order,

in the same manner.

— if installed correctly, the jaws will converge

evenly at the center of the chuck.

— if the jaws do not converge evenly, remove

them. re-install the jaws sequentially 1–3,

and make sure each one engages with the

scroll-gear lead thread during its first rota-

tion.