-50-

Model G0746/G0749 (Mfg. Since 3/13)

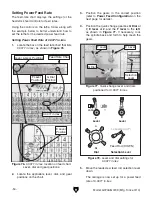

the handwheels shown in

figure 69 allow the

operator to manually move the cutting tool.

carriage Handwheel

the carriage handwheel moves the carriage left

or right along the bed. it has a graduated dial with

0.005" increments. one full revolution moves the

carriage 0.55".

cross Slide Handwheel

the cross slide handwheel moves the tool toward

and away from the work. adjust the position of

the graduated scale by loosening the thumb

knob, holding the handwheel with one hand and

turning the dial with the other, then tightening the

thumb knob. the cross slide handwheel has a

direct-read graduated dial, which shows the total

amount of material removed from the diameter

of the workpiece. the dial has 0.004" (0.01mm)

increments, and one full revolution moves the

slide 0.200". rotate the dial collar 180° to read in

metric units.

compound Rest Handwheel

the compound rest handwheel moves the cutting

tool linearly along the set angle of the compound

rest. adjust the position of the graduated scale

in a similar manner with the handwheel and dial.

the compound rest angle is set by hand-rotating

it and securing in place with four hex nuts. the

compound rest has an indirect-read graduated

dial with 0.002" (0.05mm) increments. one full

revolution of the handwheel moves the slide

0.200".

figure 69. Carriage Controls.

Carriage

handwheel

Cross slide

handwheel

Tools Needed

Qty

hex Wrench 5mm .............................................. 1

hex Wrench 8mm .............................................. 1

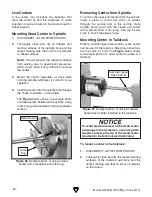

To set the micrometer stop:

1. disCoNNECt lathE FroM poWEr!

2. Use the carriage handwheel to position the

carriage and cutting tool at the desired stop-

ping point, then loosen the front cap screws

on the micrometer stop (see

figure 68).

Use the micrometer stop as a guide to help judge

when to stop carriage movement.

The micrometer stop on this lathe will

NOT automatically stop the carriage during

threading operations when the carriage

is engaged with the leadscrew! failure to

heed this notice could result in the carriage

crashing and causing severe machine or

property damage.

Micrometer Stop

3. Move the micrometer stop up to the carriage,

loosen the rear cap screws, then adjust the

graduated dial to fine-tune the position.

4. re-tighten all the cap screws.

5. Verify that tooling will not make contact with

the chuck, jaws, or other components.

figure 68. Micrometer stop.

rear Cap

screws

Front Cap

screws

graduated

dial

Compound

rest

handwheel

Manual feed