Model G0746/G0749 (Mfg. Since 3/13)

-67-

Lubrication

Use the information in the charts below as a daily

guide for lubrication tasks. We recommend using

grizzly t23962 (iso 68) or t23963 (iso 32) lubri-

cants (see

Accessories, page 64) for most of the

lubrication tasks.

NOTICE

The recommended lubrication is based on

light-to-medium usage. Keeping in mind

that lubrication helps to protect the value

and operation of the lathe, these lubrication

tasks may need to be performed more fre-

quently than recommended here, depend-

ing on usage.

failure to follow reasonable lubrication

practices as instructed in this manual could

lead to premature failure of lathe compo-

nents and will void the warranty.

Headstock

oil type .... grizzly t23963 or iso 32 Equivalent

oil amount ........................................... 18 Quarts

Check/add Frequency ................................. daily

Change ................. Every 1000 operating hours

the headstock gearing is lubricated by an oil bath

that distributes the lubricant with the motion of the

gears, much like an automotive manual transmis-

sion. Change the oil after the first 300 hours of

use, then every 1000 hours.

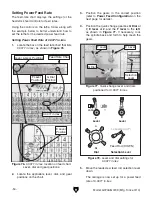

Checking Oil Level

the headstock reservoir has the proper amount of

oil when the oil level in the sight glass is approxi-

mately halfway. the oil sight glass is located

on the right side of the headstock, as shown in

figure 111.

figure 111. location of headstock oil sight

glass.

headstock

oil sight

glass

Lubrication Task

frequency page

Ref.

headstock

daily

63

Quick-Change gearbox

daily

68

apron

daily

69

Bedways

daily

69

longitudinal leadscrew

daily

69

Ball oilers

daily

70

End gears

Every 1000

hours

71

Lubrication frequency

Lubrication Task

Oil Type Amount

headstock

iso 32

18 Qt.

Quick-Change gearbox

iso 68

9.5 Qt.

apron

iso 68

6.5 Qt.

Bedways

iso 68

As

Needed

longitudinal leadscrew

iso 68

As

Needed

Ball oilers

iso 32

1–2

Squirts

End gears

Nlgi #2

Dab

Lubrication Amount & Type

items Needed

Qty

Wrench 13mm ................................................... 1

Wrench 14mm ................................................... 1

Wrench 24mm ................................................... 1

5 gallon Catch pan ........................................... 1

pump-type oil Can w/plastic Cone tip ............ 1