Model G0750GV (Mfd. Since 03/18)

-69-

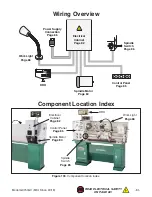

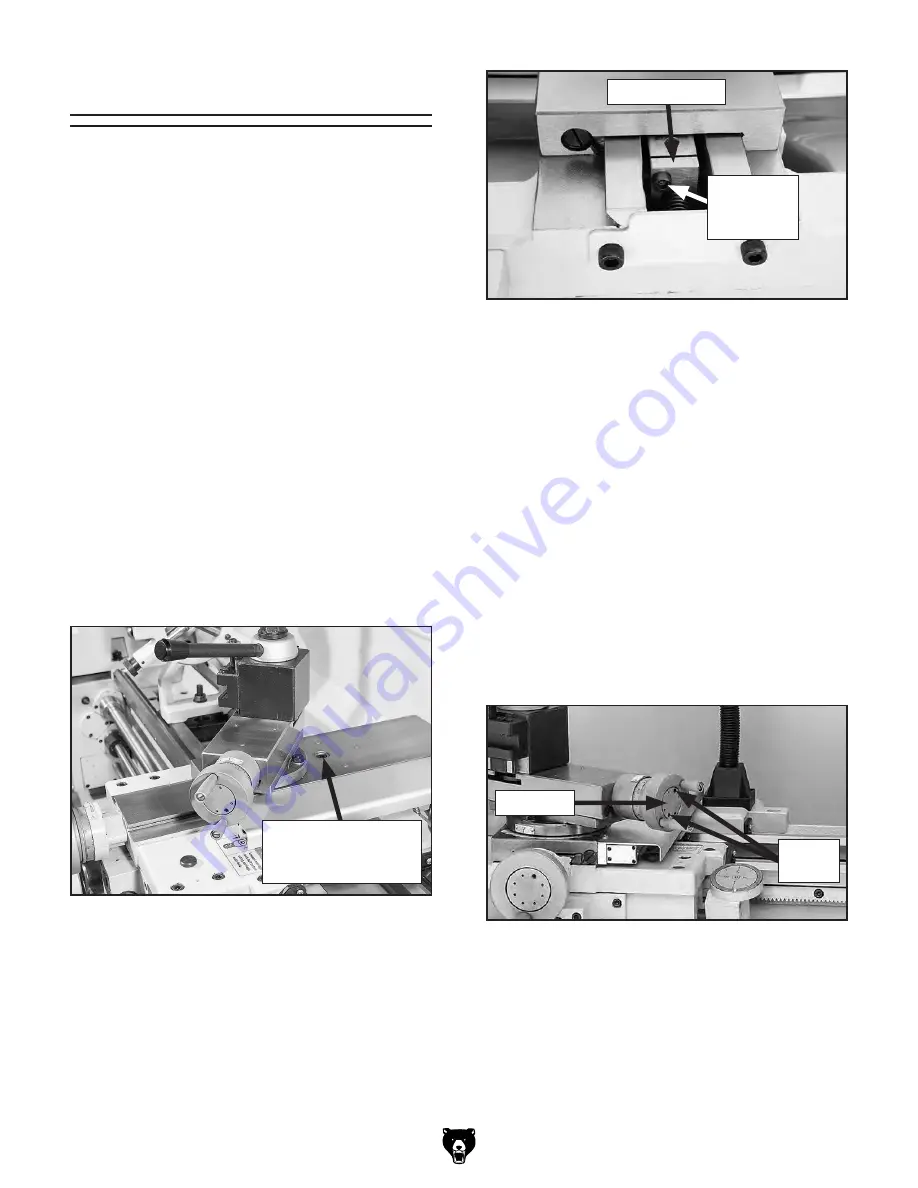

Backlash Adjustment

4. Tighten backlash adjustment cap screw

shown in

Figure 116 in small increments.

5. Hold leadscrew nut and test after each

adjustment by rotating handwheel back and

forth until backlash amount is acceptable.

6. Feed leadscrew nut back under cross slide

and replace cap screw removed in

Step 2.

Backlash is the amount of play in a leadscrew

and can be felt as the free play in a handwheel

when changing direction of rotation. The amount

of the backlash can be viewed on the handwheel

micrometer-collar graduated dial.

When adjusting backlash, tighten the components

enough to remove backlash, but not so much that

the components bind the leadscrew, making it

hard to turn. Overtightening will cause excessive

wear to the sliding block and leadscrew.

Items Needed

Qty

Hex Wrench 6mm .............................................. 1

Hex Wrench 5mm .............................................. 1

Punch Pin 2mm ................................................ 1

Cross Slide Backlash

1. Feed cross slide toward front of machine until

it reaches end of its travel.

2. Remove cap screw that secures cross slide

leadscrew nut (see

Figure 115).

Compound Slide Backlash

1. Turn compound slide handwheel counter-

clockwise several turns.

2. Loosen set screws on compound slide face-

plate several turns (see

Figure 117).

3. Use punch pin to loosen faceplate and turn

it until backlash is approximately 0.002"–

0.003", as indicated on graduated dial.

4. Secure setting with set screws.

5. Repeat adjustments above if necessary.

3. Rotate cross slide handle clockwise to feed

leadscrew nut out from under cross slide, as

shown in

Figure 116.

Figure 115. Location of cap screw that secures

the leadscrew nut.

Cap Screw Securing

Leadscrew Nut

to Cross Slide

Figure 116. Leadscrew nut location and

adjustment.

Leadscrew Nut

Backlash

Adjustment

Cap Screw

Figure 117. Compound slide backlash

adjustments.

Set

Screws

Faceplate

Summary of Contents for G0750GV

Page 116: ......