Model G0750GV (Mfd. Since 03/18)

-79-

To confirm that bearings are correctly

preloaded:

1. Re-attach all removed lathe components and

prepare it for operation.

2. Install chuck and tighten jaws.

3. Set spindle speed range lever to high.

4. Connect lathe to power and turn lathe spindle

ON. Increase spindle speed to maximum

using variable spindle-speed dial.

5. Let lathe run for 20 minutes, periodically shut-

ting it down and checking temperature.

6. Turn spindle OFF, disconnect lathe from

power, and check temperature of spindle.

— If spindle nose is slightly warm to the

touch, you have correct bearing preload.

— If spindle nose is hotter than you can com-

fortably keep your hand on, the preload is

too tight and you must repeat bearing pre-

load adjustment procedure. When repeat-

ing the procedure, rotate inner spanner

nut a little less during

Step 12 in the pre-

ceding instructions.

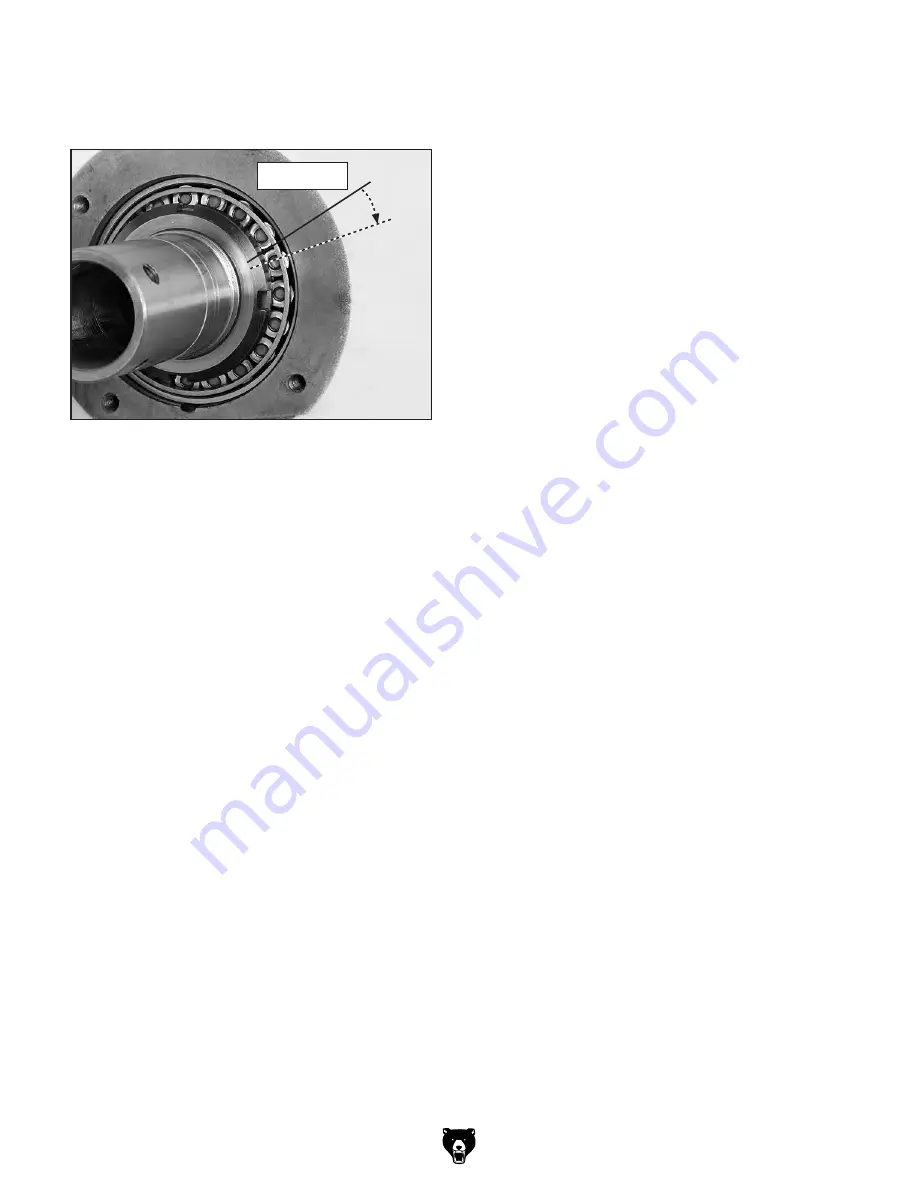

12. Tighten spanner nut an additional

1

⁄

16

" along

its circumference. See

Figure 138 for exam-

ple of this measurement.

Figure 138. Final spanner nut rotation.

1

⁄

16

" Travel

13. Without allowing inner spanner nut to tighten

any further, install and tighten outer spanner

nut against inner nut.

Note: Do not overtighten the outer spanner

nut because additional preload can force the

bearings even tighter against the races in the

headstock and cause the headstock to com-

press, or crack, or cause bearing failure.

14. Re-install outboard spindle cover.

Summary of Contents for G0750GV

Page 116: ......