-20-

Model G0765 (Mfd. Since 5/15)

5. Press tab in on side of Emergency Stop

button, lift switch cover, and press green

ON button to reset Emergency Stop button.

The spindle speed display and power button

should illuminate to indicate that lathe is con-

nected to power supply.

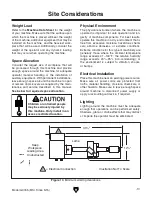

4. Disengage half nut with lever shown in

Figure 17.

Figure 17. Half nut lever disengaged.

Engaged

Halfnut

Lever

Disengaged

6. Verify lathe is operating correctly by turn-

ing spindle direction switch to "F" position.

Slowly turn variable speed dial clockwise

until spindle speed display shows 100 RPM.

The spindle should rotate counterclockwise—

down and toward the front of the lathe.

7. Push Emergency Stop button to turn lathe

OFF. Then, without resetting Emergency

Stop button, try to restart spindle rotation by

turning variable speed dial all the way coun-

terclockwise to "0" and then clockwise. The

spindle should not start.

—If spindle does start with Emergency Stop

button pressed in, the button is not oper-

ating correctly. This safety feature must

operate properly before continuing opera-

tion. Turn variable speed dial counterclock-

wise to "0" to stop lathe, disconnect it from

power, and call Tech Support for help.

Congratulations! The test run is complete. Turn

lathe

OFF and perform the following Spindle

Break-In procedure.

Half Nut

Lever

Thread Dial

Summary of Contents for G0765

Page 76: ......