Model G0765 (Mfd. Since 5/15)

-25-

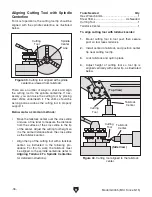

This 3-jaw, scroll-type chuck has an internal scroll-

gear that moves all jaws in unison when adjusted

with the chuck key. This chuck holds cylindrical

parts on-center with the axis of spindle rotation

and can be rotated at high speeds if the workpiece

is properly clamped and balanced.

Never mix jaw types or positions to

accommodate an odd-shaped workpiece. The

chuck will spin out of balance and may throw the

workpiece! Instead, use an independent jaw chuck

or a faceplate.

Insufficient

Jaw Clamping

Unstable

Workpiece

Bar Stock

Cylinder

Unsafe Jaw Position

Poor Scroll

Gear Engagement

Safer Inside

Jaw Use

Unsafe Inside

Jaw Use

Unsafe Jaw

Position

Safer Outside

Jaw Use

Poor Scroll Gear Engagement

Unsafe Jaw Position and

Poor Scroll

Gear

Engagement

Poor Grip

Unstable

Workpiece

Shallow

Bar Stock

Shallow

Bar Stock

Safer Outside

Jaw Use

Safer Inside

Jaw Use

CORRECT

CORRECT

CORRECT

CORRECT

INCORRECT

INCORRECT

INCORRECT

INCORRECT

Scroll Chuck

Clamping

Figure 22. Jaw selection and workpiece holding.

Changing Jaw Set

The 3-jaw scroll chuck included with the lathe

features inside and outside hardened steel jaw

sets (see

Figure below), which move in unison to

center a concentric workpiece.

When installing the jaws, it is important to make

sure they are installed correctly. Incorrect installa-

tion will result in jaws that do not converge evenly

and are unable to securely clamp a workpiece.

Jaws are numbered from 1–3 (see

Figure below).

The number is typically stamped on the side or

bottom. Jaws are designed to be installed coun-

terclockwise in numerical order in the jaw guides,

so they will hold a concentric workpiece evenly.

Figure 23. Chuck and jaw selection.

Inside Set

Outside Set

Figure 24. Jaw guide and jaw numbers.

Jaw Guides

1

2

3

Jaw Numbers

Summary of Contents for G0765

Page 76: ......