Model G0768/G0769 (Mfd. Since 8/15)

-27-

Test Run

Once assembly is complete, test run the machine

to ensure it is properly connected to power and

safety components are functioning correctly.

If you find an unusual problem during the test run,

immediately stop the machine, disconnect it from

power, and fix the problem BEFORE operating the

machine again. The

Troubleshooting table in the

SERVICE section of this manual can help.

DO NOT start machine until all preceding

setup instructions have been performed.

Operating an improperly set up machine

may result in malfunction or unexpect-

ed results that can lead to serious injury,

death, or machine/property damage.

Serious injury or death can result from

using this machine BEFORE understanding

its controls and related safety information.

DO NOT operate, or allow others to operate,

machine until the information is understood.

To test run machine:

1. Make sure all tools and objects used during

setup are cleared away from machine.

2. Press Emergency Stop button cover (see

Figure 19) to prevent unexpected start up.

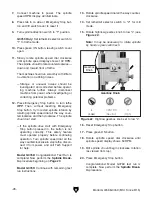

Figure 19. Headstock controls (G0769 shown).

Spindle Direction

Switch Set to "O"

Spindle Speed

Dial

Lathe/Mill

Selector Switch

Emergency

Stop Button

3. Set spindle direction switch to neutral ("0"

position), and rotate spindle speed dial all the

way counterclockwise.

G0769 Only: Set lathe/mill selector switch to

"0" (see

Figure 19 on Page on this page).

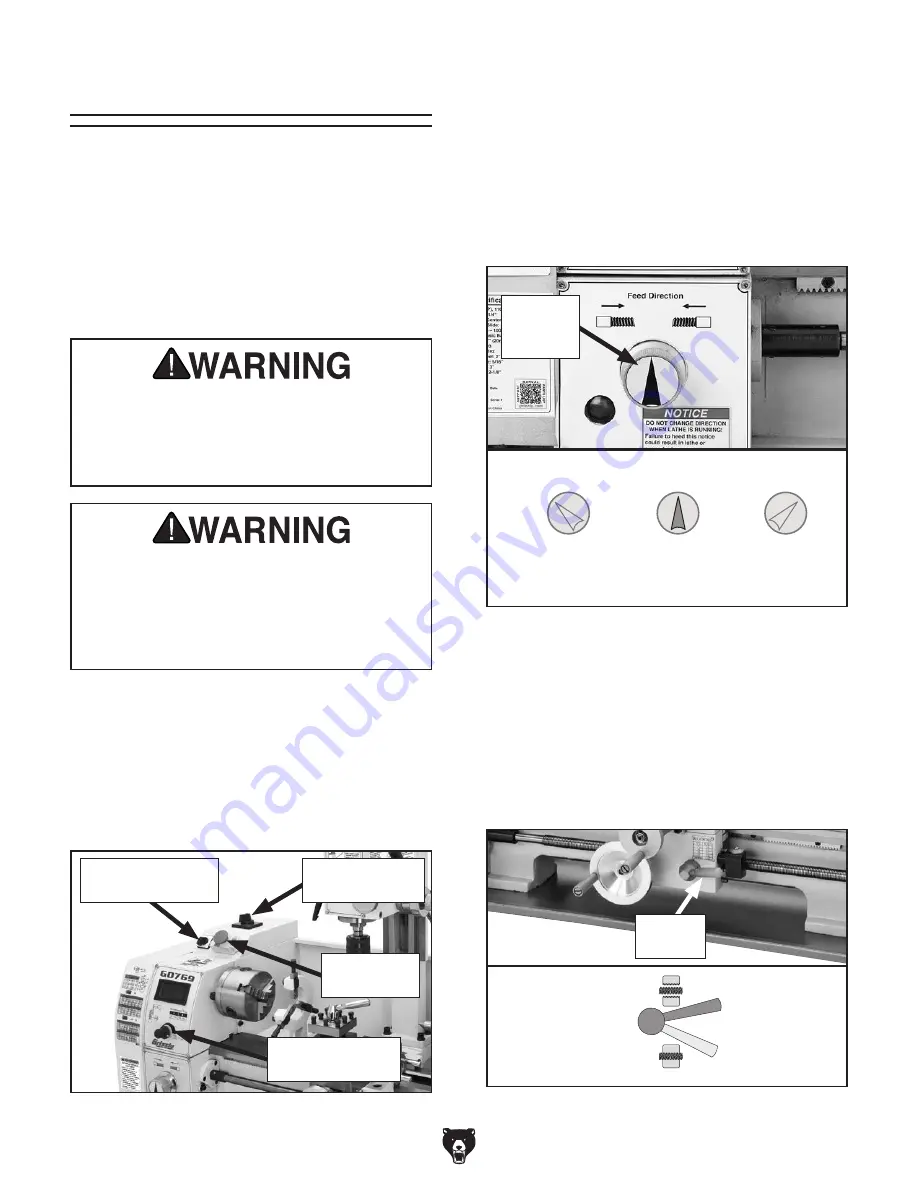

4. Shift feed direction dial to neutral (see Figure

20).

Figure 21. Half nut lever disengaged.

Half Nut

Lever

Engaged

Half Nut

Lever

Disengaged

5. Make sure chuck and jaws, if installed, are

secure (see

Chuck Installation on Page 32).

Note: If a chuck is not installed on the lathe,

you do not need to install one for this test run.

6. Disengage half nut with lever shown in

Figure 21.

Figure 20. Neutral feed direction dial setting.

Feed Direction Dial

LEFT

(Clockwise Rotation)

RIGHT

(CCW Rotation)

CENTER

(Neutral)

Feed

Direction

Lever