Model G0768/G0769 (Mfd. Since 8/15)

-41-

Figure 43 shows the MT#2 and MT#3 dead cen-

ters included with the lathe.

Centers

Mounting Dead Center in Spindle

1. DISCONNECT MACHINE FROM POWER!

2. Thoroughly clean and dry all mating surfaces

of spindle bore and center, making sure that

no lint or oil remains on these surfaces.

3. Mount chuck or faceplate onto spindle, which-

ever is correct for your operation.

4. Insert MT#3 center into spindle bore through

chuck or faceplate.

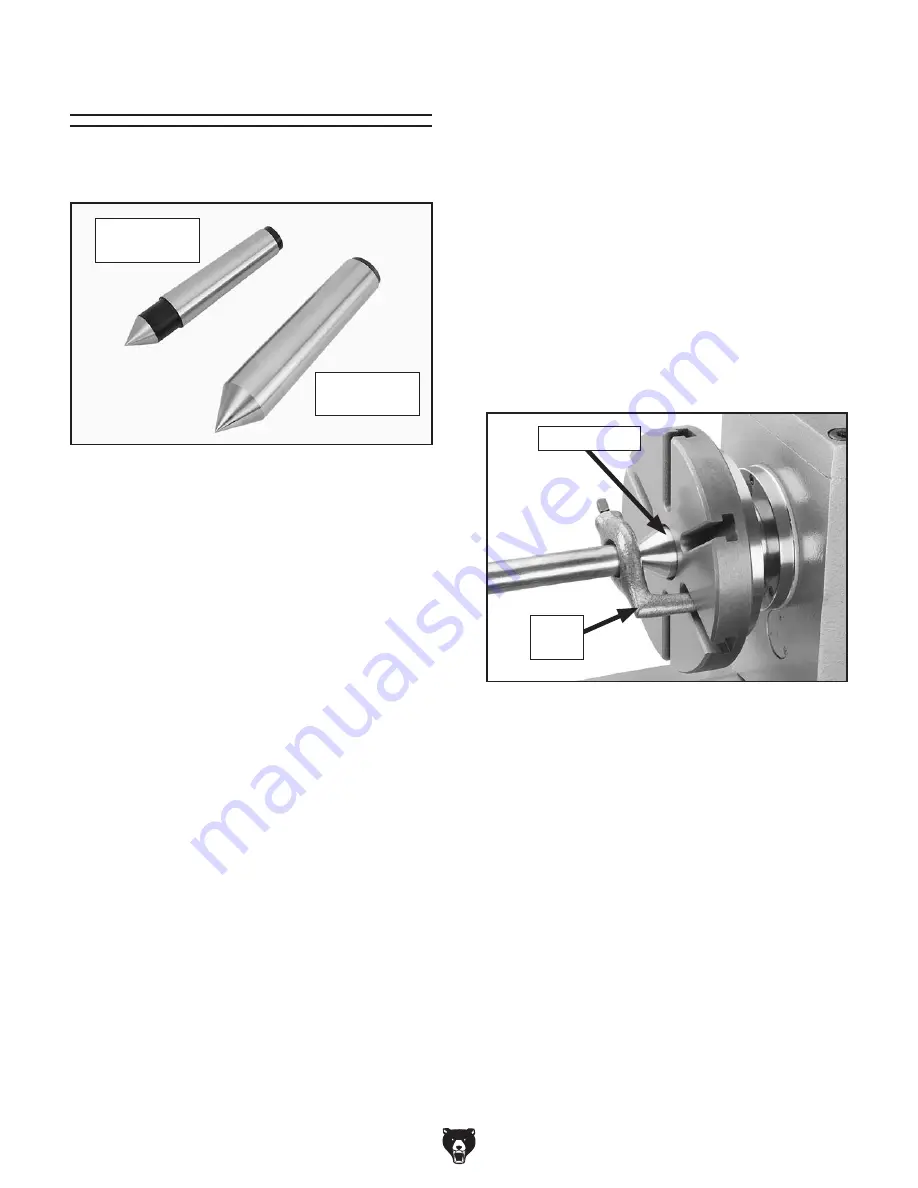

Below is an example photo of a dead center

installed in spindle, using a lathe dog and

faceplate for turning between centers.

Figure 43. Dead centers.

MT#2 Dead

Center

MT#3 Dead

Center

Dead Centers

Dead centers are one-piece, high-speed steel

centers that require low spindle speeds and a

small amount of oil to reduce friction heat that may

damage the workpiece.

Mount the MT#2 dead center (see

Figure 43)

in the tailstock. Since the workpiece will rotate

against the center and generate friction, the tip of

the center must be lubricated to avoid premature

wear and maximize smooth operation.

Mount the MT#3 dead center (see

Figure 43) in

the spindle for operations where the workpiece

rotates with the center and does not generate

friction.

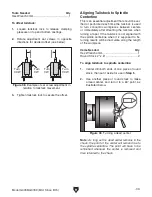

Figure 44. Example of using a dead center with

a faceplate and lathe dog.

Dead Center

Lathe

Dog

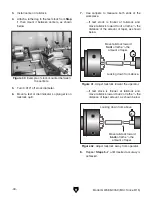

Removing Center from Spindle

To remove the center from the spindle, insert a

piece of round bar stock (or similar tool) through

the outside end of the spindle. Hold onto the cen-

ter with a gloved hand or shop rag, then tap the

bar stock to knock the center loose.