Model G0768/G0769 (Mfd. Since 8/15)

-51-

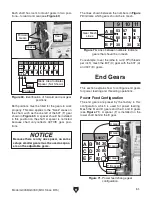

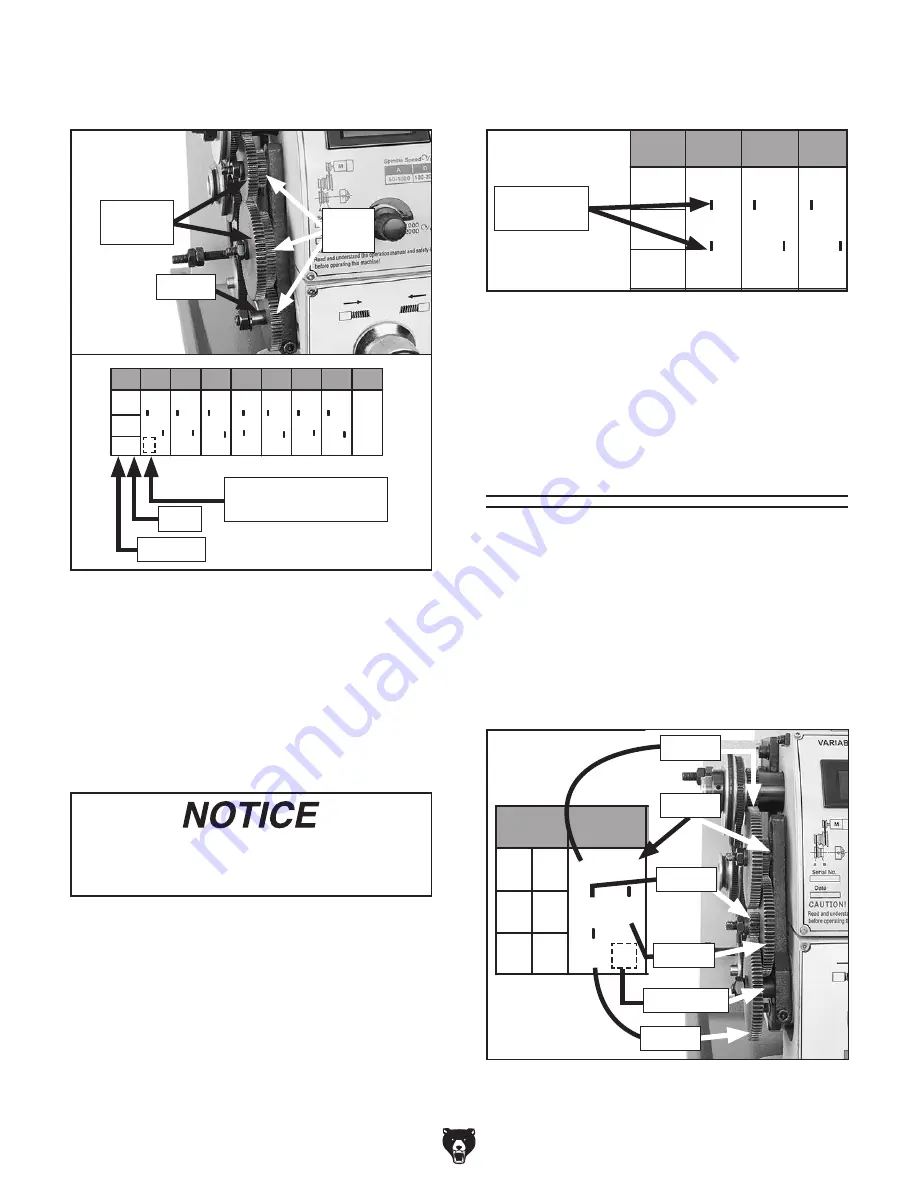

Because there is only one spacer, on some

setups smaller gears must be used as spac-

ers on the adjustable gears.

Both positions must be filled for the gears to work

properly. This also applies to the "blank" areas on

the chart, such as the one left of the 50T (F) gear

shown in

Figure 69. A spacer should be installed

in this position on the shaft. A spacer is not listed

because chart only reflects ACTIVE gear posi-

tions.

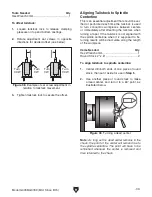

Each shaft has room to mount gears in two posi-

tions—forward and rear (see

Figure 69).

Forward

Gears

Rear

Gears

Spacer

A

C D

B

E F

A

C D

B

E F

30

19 20 22 24 32 40 44

80 80

30

33 40

65

70

80 60

60

60

60

63

63

53

9 10 11 12 13 14 16 18

50

50

55

80

80

80

80

80

8060

60

7153 55

33

30

55

55

4030

53

53

53 72

63

70

57

57 72

72

72

72 80

70 40

40

40

63

57

55

Figure 69. Identification of forward and rear gear

positions.

Forward

Blank Area Indicates

Spacer (Not Shown)

Rear

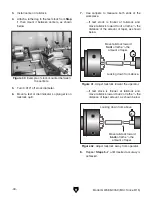

This section explains how to configure end gears

for power feeding and threading operations.

End Gears

Power Feed Configuration

The end gears are preset by the factory in this

configuration, which is used for power feeding.

Mesh the B and D gears and the C and E gears

(see

Figure 71). A spacer (F) is installed on the

lower shaft behind the E gear.

Figure 71. Power feed change gear

configuration.

0.0037"

84

20

A

A

40

C

C

D

D

B

B

E

E

F

F

80

80

80

30 72

33 80

30

0.0068"

E Gear

F (Spacer)

D Gear

C Gear

B Gear

A Gear

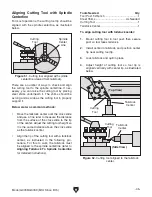

The lines shown between the numbers in

Figure

70 indicate which gears should be in mesh.

A

C D

B

E F

A

C D

B

E F

30

19 20 22 24 32 40 44

80 80

30

33 40

65

70

80 60

60

60

60

63

63

53

9 10 11 12 13 14 16 18

50

50

55

80

80

80

80

80

80 60

60

7153 55

33

30

55

55

4030

53

53

53 72

63

70

57

57 72

72

72

72 80

70 40

40

40

63

57

55

Figure 70. Lines between numbers indicate

gears that should be in mesh.

Gear Mesh

Lines

For example, to set the lathe to cut 9 TPI (threads

per inch), mesh the 80T (C) gear with the 53T (A)

and 30T (E) gears.