Model G0768/G0769 (Mfd. Since 8/15)

-55-

20. Re-install e-clips and hex nuts onto middle

and top gear shafts.

21. Adjust lash between meshed gears so it

is approximately 0.003", then tighten gear

shafts and fasteners.

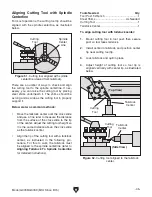

22. Swing adjuster up and mesh 53T gear with

40T spindle gear (see

Figure 86).

23. Secure adjuster cap screw.

24. Re-install end gear cover. The end gears are

now configured for 20 TPI.

Figure 86. 53T gear meshed with spindle gear.

Adjustor Cap

Screw

Spindle Gear

53T Gear

Power Feed

The carriage has power feed (or automatic feed)

options for threading or non-threading operations.

This section describes how to use the power feed

option for non-threading operations. To learn how

to power the carriage for threading operations,

refer to

Threading on Page 58.

Power Feed Controls

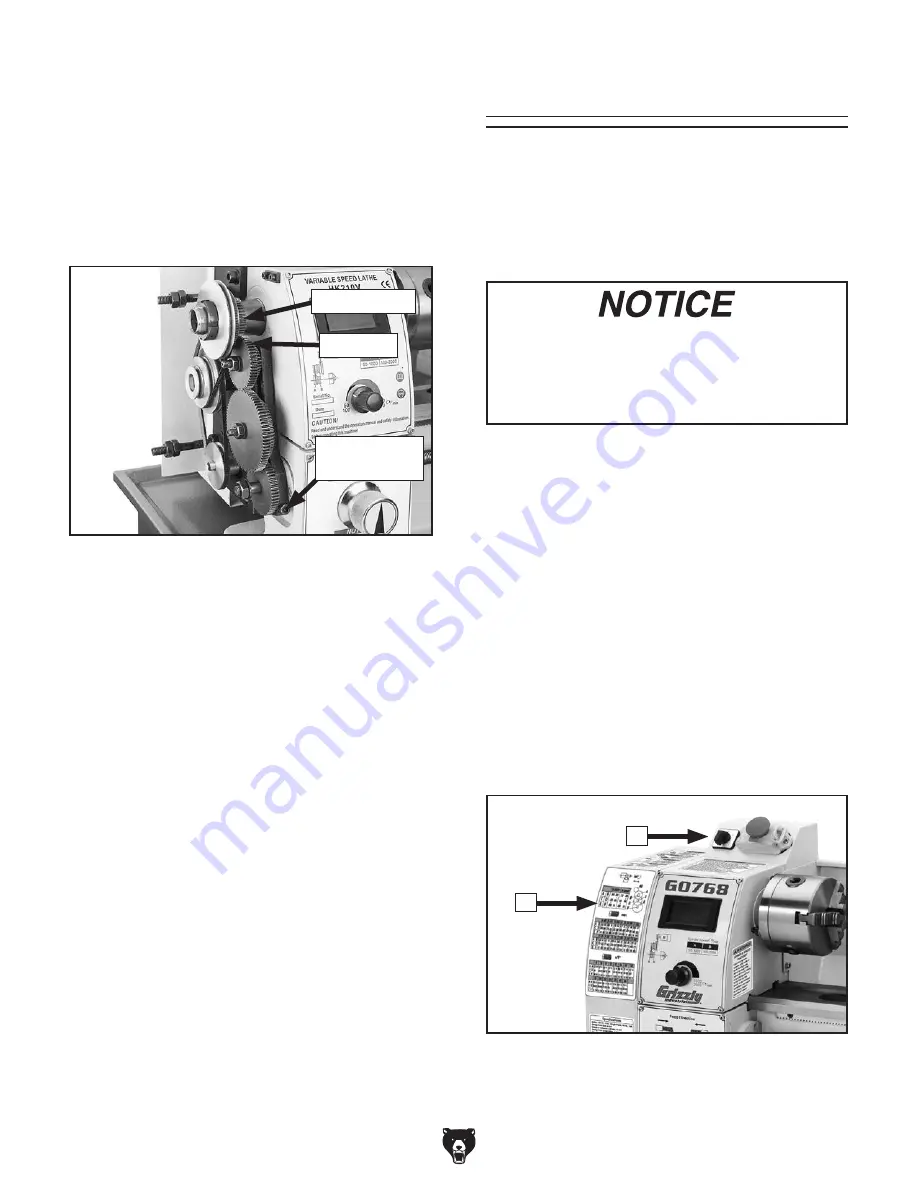

Use the following descriptions and figures to

understand the power feed controls.

Before using power feed, you may have to recon-

figure the end gears, depending on how they are

set up (refer to

Power Feed Configuration on

Page 52). The lathe comes from the factory with

the end gears set up in the power feed configura-

tion.

A. Spindle Direction Switch: Enables forward

or reverse carriage travel when feed direction

dial and half nut lever are engaged. The car-

riage will not move when the switch is in the

"0" position.

Figure 87. Spindle switch and feed rate chart.

A

B

To avoid damaging lathe, NEVER allow

cutting tool to run into chuck! ALWAYS

make sure spindle is completely stopped

BEFORE using headstock controls to make

changes.