Model G0768/G0769 (Mfd. Since 8/15)

-81-

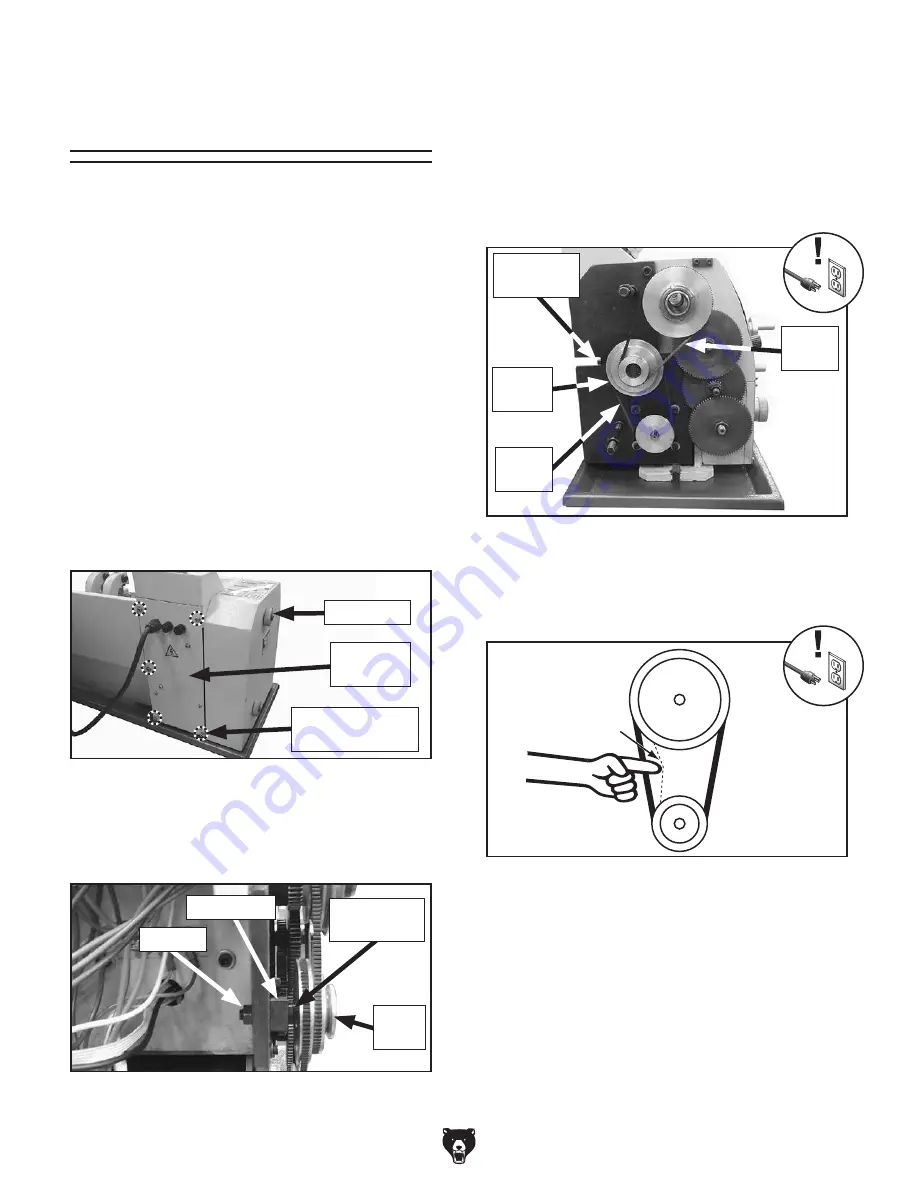

Tensioning &

Replacing V-Belts

V-belts stretch and wear with use, so it is impor-

tant to routinely monitor belt tension. V-belts that

are improperly tensioned or exposed to grease/oil

will slip and poorly transmit power from the motor.

To ensure optimal power transmission, inspect

belts on a monthly basis to verify they are properly

tensioned and free of oil/grease. Replace V-belts

when they become cracked, frayed, or glazed.

Tools Needed

Qty

Hex Wrench 3, 4mm ....................................1 Ea.

Open-End Wrench 10, 13 mm .....................1 Ea.

Pulley

Deflection

Pulley

Figure 142. Correct V-belt deflection.

1

⁄

8

"

5. Tension V-belts until there is approximately

1

⁄

8

" deflection when pushed with moderate

pressure, as shown in

Figure 142.

—If there is more than

1

⁄

8

" deflection when

the V-belts are pushed with moderate pres-

sure, adjust tension until it is correct.

6. Tighten pivot block bolt and hex nut loosened

in

Step 3.

7. Re-install and secure end cover and electri-

cal panel.

Figure 141. Tensioner screw and V-belts.

Upper

V-Belt

Tensioner

Screw

Idler

Pulley

4. Turn tensioner screw (see Figure 141) clock-

wise to tension V-belts or counterclockwise to

loosen V-belts.

—If replacing V-belts, loosen idler pulley and

carefully roll upper and lower V-belts off of

pulleys, then re-install new V-belts in same

manner.

Lower

V-Belt

To adjust tension or replace V-belts:

1. DISCONNECT MACHINE FROM POWER!

2. Remove end cover and electrical panel (see

Figure 139).

3. Using flat 10mm wrench provided with lathe,

hold pivot block bolt shown in

Figure 140,

and loosen hex nut with 13mm wrench.

Figure 140. Pivot block bolt and hex nut for

idler pulley adjustment.

Hex Nut

Pivot Block

Bolt

Pivot Block

Idler

Pulley

Figure 139. Location of parts for removing panel.

Electrical

Panel

End Cover

Cap Screws to

Remove (1 of 5)