-34-

Model G0768/G0769 (Mfd. Since 8/15)

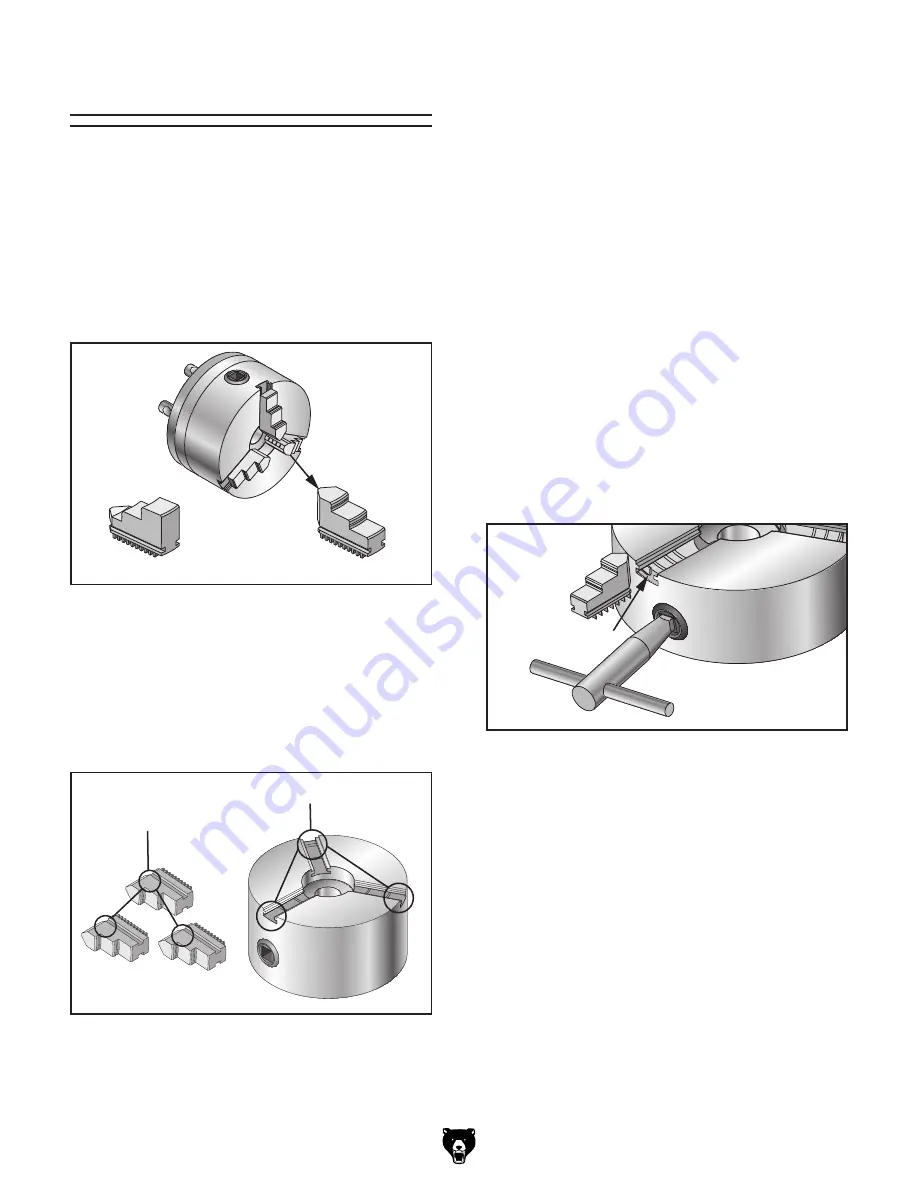

Changing Jaw Set

The 3-jaw scroll chuck included with the lathe

features inside and outside hardened steel jaw

sets (see

Figure below), which move in unison to

center a concentric workpiece.

When installing the jaws, it is important to make

sure they are installed correctly. Incorrect installa-

tion will result in jaws that do not converge evenly

and are unable to securely clamp a workpiece.

Jaws are numbered from 1–3 (see

Figure below).

The number is typically stamped on the side or

bottom. Jaws are designed to be installed coun-

terclockwise in numerical order in the matching

numbered jaw guides, so they will hold a concen-

tric workpiece evenly.

To change jaw set:

1. DISCONNECT MACHINE FROM POWER!

2. Use appropriate device to protect ways (refer

to

Installation & Removal Device subsec-

tion).

3. Insert chuck key and turn it counterclockwise

to back jaws out and remove them individu-

ally in descending order (i.e., 3, 2, 1).

4. Use mineral spirits to clean debris and grime

from jaws and chuck jaw guides.

5. Apply thin coat of NLGI #2 grease to surfaces

of removed jaw set. Store in safe place free

from moisture and abrasives.

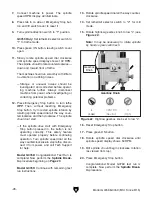

6. Rotate chuck key clockwise until you see tip

of outer scroll-gear lead thread about to enter

a jaw guide (see below).

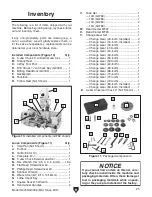

Figure 28. Chuck and jaw selection.

Inside Set

Outside Set

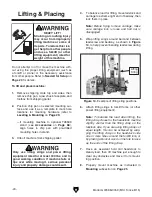

Figure 29. Jaw guide and jaw numbers.

Jaw Guides

1

2

3

Jaw Numbers

1

2

3

Lead Thread

1

1

2

3

Figure 30. Lead thread on scroll gear.

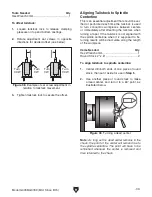

7. Insert jaw #1 into jaw guide #1 and hold jaw

against scroll-gear.

8. Rotate chuck key clockwise one turn to

engage tip of scroll-gear lead thread into jaw.

Pull jaw; it should be locked into jaw guide.

9. Install remaining jaws in numerical order, in

the same manner. The jaws should converge

evenly at center of chuck.

— If jaws do not converge evenly, remove

them. Check that jaw numbers and jaw

guides match. Re-install jaws sequentially

1–3, making sure each one engages with

scroll-gear lead thread during its first rota-

tion.