Model G0768/G0769 (Mfd. Since 8/15)

-35-

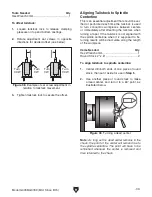

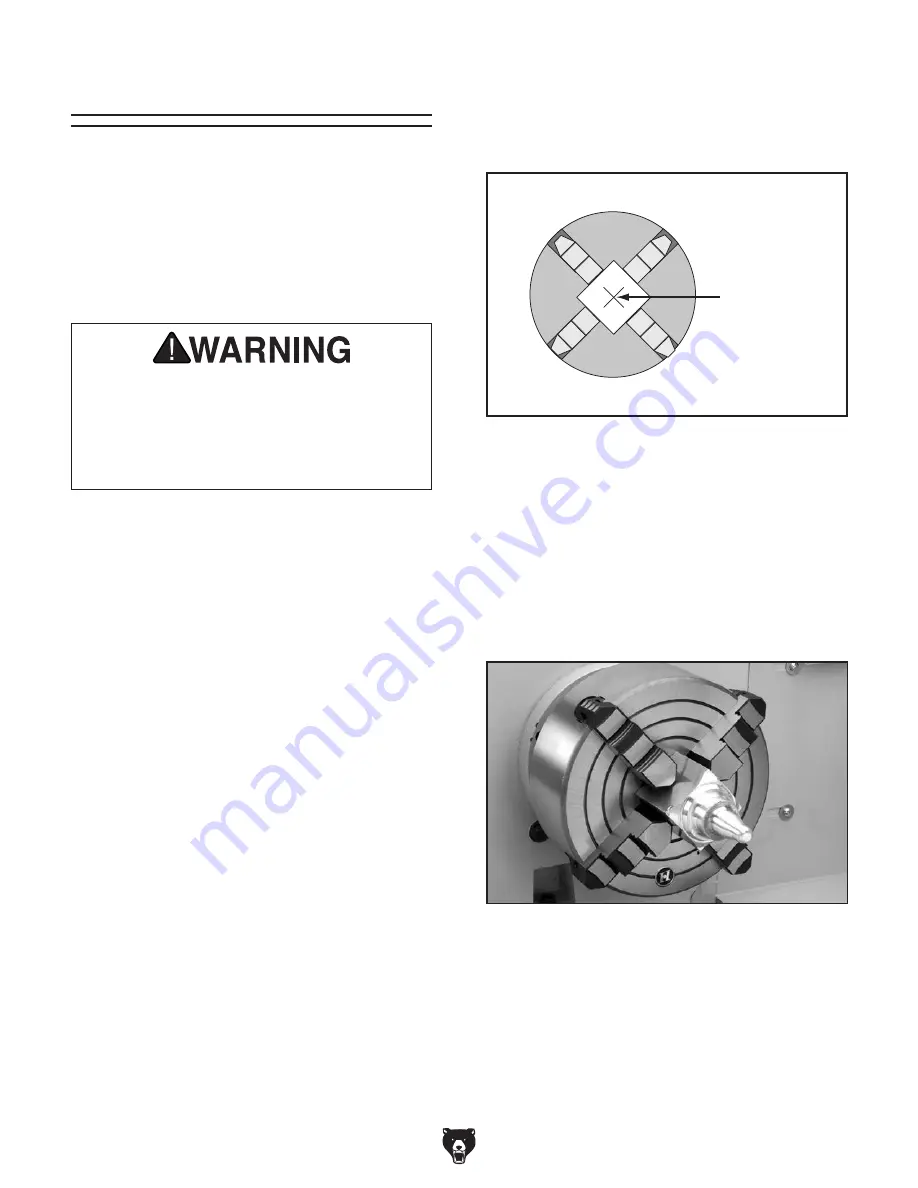

Figure 31. 4-jaw chuck tightening sequence.

1

2

3

4

Workpiece

Center Point

Figure 32. Example of a non-cylindrical

workpiece correctly positioned on a 4-jaw chuck.

4-Jaw Chuck

Refer to the

Chuck Installation subsection for

instructions on installing the 4-jaw chuck.

The 4-jaw chuck features independently adjust-

able jaws for holding non-concentric or off-center

workpieces. Each jaw can be independently

removed from the chuck body and reversed for a

wide range of work holding versatility.

Because of dynamic forces involved in

machining a non-concentric or off-center

workpiece, always use a low spindle speed

to reduce risk of workpiece coming loose

and being thrown from lathe, which could

cause death or serious personal injury.

Mounting Workpiece

1. DISCONNECT MACHINE FROM POWER!

2. Use an appropriate device to protect ways

(refer to

Chuck Safety & Support Devices

section for more details).

3. Use chuck key to open each jaw so work-

piece will fit into spindle opening and lay flat

against chuck face and jaw steps.

4. With help from another person or a holding

device, position workpiece so it is centered in

chuck.

5. Tighten each jaw in small increments. After

tightening first jaw, continue tightening

remaining jaws in an opposing sequence,

similar to sequential order shown below.

6. After workpiece is secured by jaws, use dial

indicator to make sure workpiece is centered

in chuck.

— If workpiece is not correctly centered,

make fine adjustments by slightly loosening

one jaw and tightening opposing jaw until

workpiece is correctly positioned (see

below for an example).