-64-

Model G0768/G0769 (Mfd. Since 8/15)

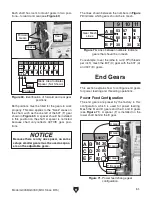

The Model G0769 features two different types of

spindle downfeed controls: coarse and fine, as

shown in

Figure 109.

Using Spindle

Downfeed Controls

Coarse Downfeed

Coarse downfeed is typically used for drilling

applications. Rotate either of the coarse downfeed

handles (see

Figure 109) to lower the spindle,

and an internal coil spring helps raise the spindle

back to the top position when you stop applying

downward pressure on the handle.

Note: To maintain control of the upward spindle

travel and the rotating bit in your workpiece,

always continue holding the handle until the

spindle returns to the top position. Letting go of

the coarse downfeed handles when the spindle

is in the lowered position will cause the spindle to

retract too quickly and slam up into the headstock

or lift the workpiece and cause it to spin out of

control.

The coarse downfeed hub features a graduated

dial that measures spindle movement in 0.02"

increments, with one full revolution equaling 2.00"

of spindle travel.

Fine Downfeed

Fine downfeed is typically used for milling applica-

tions, because the spindle only moves up or down

when the fine downfeed handwheel (see

Figure

109) is rotated (there is no automatic spindle

return to the top position, as with the coarse

downfeed controls). This allows the spindle height

to be locked in place for precise Z-axis positioning

of a cutter or end-mill when milling a flat surface

across the face of a workpiece. In order to ensure

the milled surface remains flat, the spindle height

cannot move until the entire milling operation is

complete.

The fine downfeed graduated dial measures spin-

dle movement in 0.001" increments, with one full

revolution equaling 0.080" of spindle travel.

Engaging Fine Downfeed Controls

In the following example, the fine downfeed

controls are used to mill 0.010" off a workpiece:

1. Use vertical travel handwheel (see Figure

105 on next page) to adjust cutting tool just

above workpiece surface, then secure the

headstock with Z-axis lock levers.

2. Tighten downfeed selector knob (see Figure

109) to engage fine downfeed handwheel.

3. Loosen quill lock lever.

4. Rotate fine downfeed handwheel clockwise

and lower cutting tool so it just touches

workpiece.

5. Move workpiece out of the way.

6. Using graduated dial to gauge spindle move-

ment, rotate fine downfeed handwheel clock-

wise 0.010".

7. Tighten quill lock lever.

8. Turn mill/drill ON and perform cutting pass.

Figure 109. Spindle controls.

Quill Lock

Lever

Fine

Downfeed

Handwheel

Coarse

Downfeed

Handle

Downfeed

Selector

Knob

Graduated Dials