-38-

Model G0781 (Mfd. Since 2/15)

SHOCK HAZARD. Working on wiring that is con-

nected to a power source is extremely dangerous.

Touching electrified parts will result in personal

injury including but not limited to severe burns,

electrocution, or death. Disconnect the power

from the machine before servicing electrical com-

ponents!

MODIFICATIONS. Modifying the wiring beyond

what is shown in the diagram may lead to unpre-

dictable results, including serious injury or fire.

This includes the installation of unapproved after-

market parts.

WIRE CONNECTIONS. All connections must

be tight to prevent wires from loosening during

machine operation. Double-check all wires dis-

connected or connected during any wiring task to

ensure tight connections.

CIRCUIT REQUIREMENTS. You MUST follow

the requirements at the beginning of this manual

when connecting your machine to a power source.

WIRE/COMPONENT DAMAGE. Damaged wires

or components increase the risk of serious per-

sonal injury, fire, or machine damage. If you notice

that any wires or components are damaged while

performing a wiring task, replace those wires or

components.

MOTOR WIRING. The motor wiring shown in

these diagrams is current at the time of printing

but may not match your machine. If you find this

to be the case, use the wiring diagram inside the

motor junction box.

CAPACITORS/INVERTERS. Some capacitors

and power inverters store an electrical charge for

up to 10 minutes after being disconnected from

the power source. To reduce the risk of being

shocked, wait at least this long before working on

capacitors.

EXPERIENCING DIFFICULTIES. If you are expe-

riencing difficulties understanding the information

included in this section, contact our Technical

Support at (570) 546-9663.

Wiring Safety Instructions

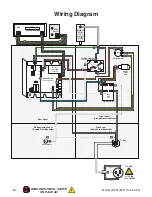

The photos and diagrams

included in this section are

best viewed in color. You

can view these pages in

color at www.grizzly.com.

These pages are current at the time of printing. However, in the spirit of improvement, we may make chang-

es to the electrical systems of future machines. Compare the manufacture date of your machine to the one

stated in this manual, and study this section carefully.

If there are differences between your machine and what is shown in this section, call Technical Support at

(570) 546-9663 for assistance BEFORE making any changes to the wiring on your machine. An updated

wiring diagram may be available.

Note: Please gather the serial number and manufacture date of your

machine before calling. This information can be found on the main machine label.

SECTION 8: WIRING

machine

Summary of Contents for G0781

Page 52: ......