Model G0792 (Mfd. Since 12/15)

-23-

SECTION 6: MAINTENANCE

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check

•

Loose mounting bolts.

•

Worn or damaged wires.

•

Any other unsafe condition.

As Needed

•

Check/adjust lubrication of leadscrew.

•

Check/adjust lubrication of drive gears.

Schedule

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

For optimum performance, periodically check

and, if necessary, lubricate the leadscrew and

drive gears.

Items Needed

Qty

Hex Wrench 6mm .............................................. 1

Hex Wrench 4mm .............................................. 1

Mineral Spirits .................................... As Needed

Small Brushes ................................................... 2

Way Oil ISO 68 .................................. As Needed

Grease NLGI#2 ................................. As Needed

Lubrication

Cleaning the Model G0792 is relatively easy.

Wipe down all unpainted and machined surfaces

daily to keep them rust free and in top condition.

This includes any surface that is vulnerable to rust

if left unprotected. Use ISO 68 way oil or any other

quality metal lubricant (see

Page 22 for offerings

from Grizzly) to prevent corrosion.

Cleaning &

Protecting

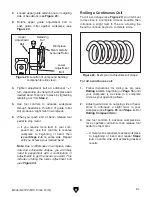

To access leadscrew and drive gears:

1. DISCONNECT MACHINE FROM POWER!

2. Remove M5-.8 x 12 cap screw and drive shaft

cover from back of machine (see

Figure 28).

3. Remove (6) M8-1.25 x 16 cap screws and

drive gear cover (see

Figure 28).

Figure 28. Components to remove before

lubricating leadscrew and drive gears.

Drive Gear

Cover

Drive Shaft

Cover

Cap Screw

M8-1.25 x 16

Cap Screw

M5-.8 x 12

4. Lubricate leadscrew and drive gears (see

Figure 29 on Page 24), as necessary.

5. Re-install drive gear cover and drive shaft

cover.

Summary of Contents for G0792

Page 44: ......